The Origins of the Australian

Plug and other Electrical Trivia.

Most people never give it any thought every

time they plug in an appliance, but have you considered where the design

of the three pin plug and socket configuration used in Australia, NZ, and

the South Pacific came from? Did you know it is actually an American design

(albeit obsolete) we are using? Read on if this interests you...

Being part of the British Empire, it was

natural that Australasia would choose British wiring methods. So it was

hardly surprising that 200-250V mains supplies were adopted, and

what was then called the "Swan" base (soon to be known simply as the B22

bayonet base) light socket (after the British inventor of the incandescent

light bulb). But what of the sockets for portable appliances?

Need for connection of portable appliances.

Electricity supply to homes was initially

provided for lighting only, so the ubiquitous socket on the wall, otherwise

known as a power point (or GPO - General Purpose Outlet, in electrical

parlance) did not exist at the time. At the end of the 19th century there

were no domestic appliances as we know them today; just carbon filament

light bulbs.

Refrigeration was not yet in a form suitable

for domestic use; there was no radio or TV, and heating/cooking appliances

were happily being run from combustible fuel. However, this being a time

of creative invention meant that other uses were seen for this electric

supply, and soon enough came an explosion of all kinds of appliances with

"clean" and "labour saving" attributes to their claim. Being prior to the

electronic age, such appliances were invariably based around motors and/or

heating elements. Table fans, toasters, irons, etc. started to appear.

Having acquired such an appliance the next thing to consider was where

to plug it in. The only place of course was into a light socket. So, appliances

came fitted with bayonet plugs. In order to use the appliance and not be

in the dark at the same time, bayonet double adaptors were available, with

one socket used for the light bulb and the other for the appliance. Some

even had a switch on one of the sockets. While this method works, the disadvantages

are that one has to climb up to the light socket every time to connect

or disconnect the appliance. Also, the light socket can only handle a maximum

of 3 to 5A - no good for a 2.4KW radiator! And thirdly, no earthing connection

is available. Nevertheless, this method of connecting low power appliances

was still common into the 1950's, and it is not uncommon to see advertisements

for appliances at the time fitted with a bayonet plug.

This bayonet double adaptor allows an appliance to be plugged into

a light socket while retaining the light bulb. South Africa, where

this one was made, was part of the British Empire and hence adopted the

B22 bayonet light socket, as well as the British round pin mains sockets.

How appliances were connected before wall mounted power points.

With desk and standard lamps appearing,

wall mounted sockets were seen as far more practical. And yes, the bayonet

socket was sometimes used for this purpose. In the U.S, a plug and socket

was developed by Harvey Hubbell with two flat parallel blades, to take

the place of the Edison screw socket, for portable appliance connection.

Flat blades were chosen to mimic a knife switch with its inherently reliable

contacts. In Britain and Europe various incompatible round pin configurations

were used. While the UK introduced yet another plug, in 1949, which was

to be the new standard which remains to this day, continental Europe has

persisted with a multitude of incompatible plug designs, although the 2

pin "Europlug" goes a long way to solve this problem for double insulated

appliances, at least.

Typical of early appliances is this radiator and toaster from the

1920's. Note the bayonet plug for the toaster.

In Australia.

By the 1920's Australia was using the

British round pin plug and socket, but the two flat pin American plug had

also found its way here and was also in use.

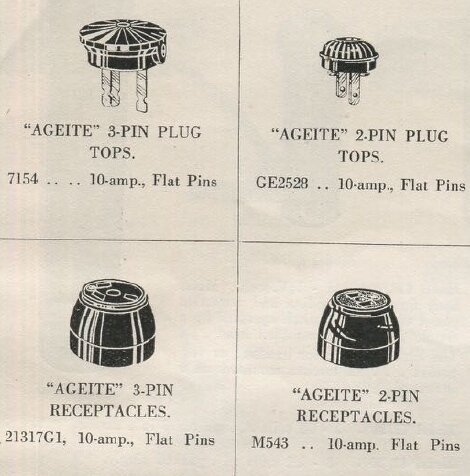

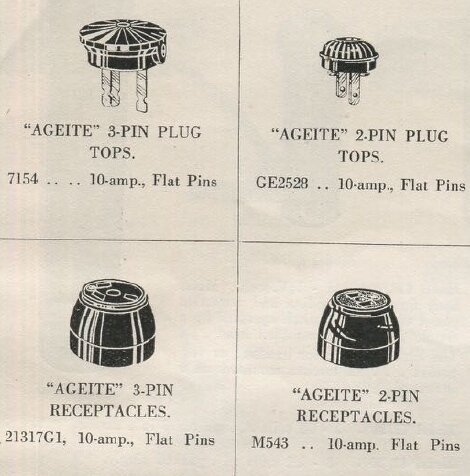

Typical of the plugs and sockets in use before standardisation.

From L-R; three pin English, two pin English, two pin U.S. and three pin

U.S.

Sometimes one still sees ancient examples

of these fittings in second hand building material suppliers, still on

their wooden mounting blocks. Clipsal still make the parallel two pin plug

and socket which is approved for 250V, although these days it's usually

used with imported 120V equipment. However, the polarised version of this

plug which later appeared in the U.S., having a wider neutral pin, was

never used here. This can be problematic with some Australian made step

down transformers, when modern U.S appliances are to be plugged into them,

since the wider pin does not fit. It appears to be unknown to many Australians

that the U.S has had 3 pin and polarised two pin plugs for some time now.

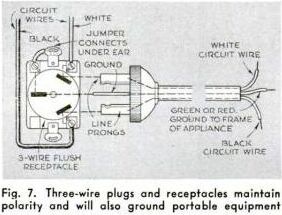

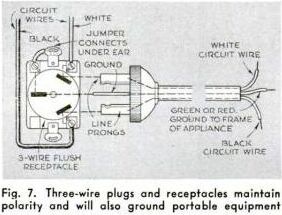

Modern NEMA 5-15 plugs and sockets used in the U.S. for 120V. Note

the wider neutral pin on the two pin plug - it will not fit non polarised

sockets.

While electrical safety wasn't given the

attention that gets these days, it was realised that earthing of appliances

was a necessity, and thus three pins were required.

Both the British and Americans had a three

pin plug which were being used here. The British plug was of course was

a round pin design, while the American one used flat pins. The American

plug was not however their three pin plug of today (known as NEMA 5-15)

but had two angled pins for the supply and another flat pin beneath for

the earth. It is what most would recognise today as the "Australian" plug.

The Hubbell Design.

This three pin plug design was designed

by Hubbell, and patented in 1916. Hubbell still exists to this day as a

prominent manufacturer of electrical accessories in the U.S.

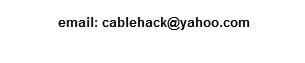

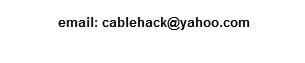

Original Hubbell patent.

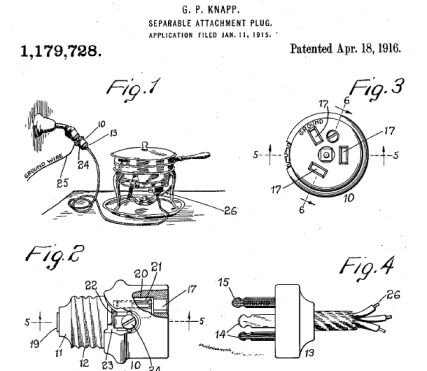

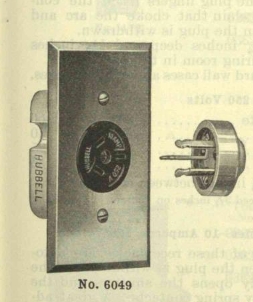

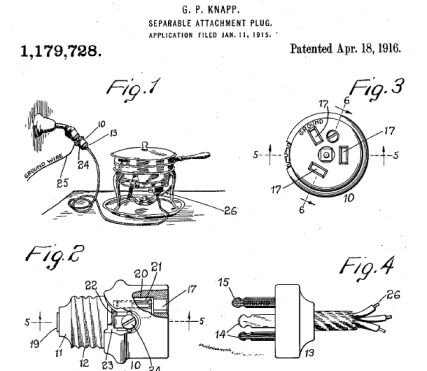

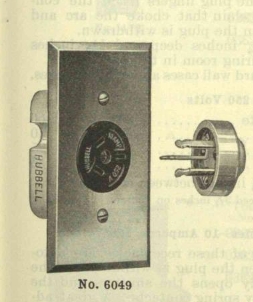

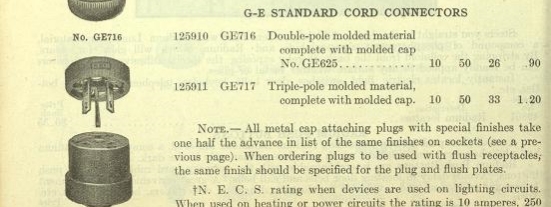

Left image is from a Canadian GE catalog in 1915. On the right is

from a 1920 catalog.

Examples of U.S. made sockets. These are currently in use in the

U.S., and connected for 240V (courtesy of WA2ISE).

Examples such as these sometimes appear on the U.S. eBay.

Hubbell adaptor seen on the U.S. eBay.

Hubbell porcelain socket. It is obvious that Australian manufacturers

based their designs on this.

They are not particularly rare in the U.S. Here's one in a collection

of plugs seen on eBay.

More sockets on eBay from the U.S.

This early 3 pin plug design was not popular

in the U.S. because of incompatibility with their existing two pin plug.

Nevertheless, there are plenty of surviving examples as evident from U.S.

eBay ads.

Closer to home, this GE socket was attached to an ancient homemade

switchboard from the late 1920's -early 30's. The British socket on the

right was found buried in my backyard. It was probably part of the original

wiring in my house. Unfortunately, the cover, made of wood, was long

gone. Fittings such as these are usually mounted on wooden blocks.

Australian made 2 flat pin double adaptor.

It is mentioned in the Australian magazine,

" Radio & Hobbies in Australia", in one of the "The Serviceman Who

Tells" articles from the 1950's, that one thing required for the service

bench should be a bayonet socket, a two flat pin socket and a round pin

socket. It was stated that although these fittings were not approved, there

were still some radios fitted with such plugs.

This surviving example of a U.S. made (General Electric U.S.A) power

point is located in an old house in the Central West of NSW. Although still

connected, it is doubtful anything has been plugged in for many years.

This socket allows for the insertion of tandem blade plugs (horizontal

pins) as well as the more common parallel pin plugs. The parallel pin socket

is modern enough for it to be polarised - note that one pin is narrower

than the other. Unlike the U.S., however, power points

in Australia are required to be fitted with an adjacent switch.

Around 1930 an attempt was made by Clipsal

and Ring Grip (the predominant electrical accessory manufacturers at the

time), along with the State Electricity Commission of Victoria to

adopt the American design as the Australian standard. Associated General

Electric was importing the American design from its U.S. counterpart, General

Electric, and promoting its use in Australia.

Associated General Electric plugs and sockets from a 1938 catalog.

The American design was chosen over the

British design because it was easier for local manufacturers to make flat

pins instead of round ones.

This was one of several newspaper articles from 1929-30 explaining

the problem of having around 70 types of plug and socket in use and the

need to standardise. The article states:

"Efforts now being made by the Electrical Association of N.S.W. to

standardise the types of power plugs in use will receive enthusiastic endorsement

from many consumers.

The necessity for improvement along this line is indicated by the

results of the association's investigations. In reviewing the existing

position, a collection was made of every plug on the market. The amazing

result was an array of 71 distinct versions.

This evidence of the versatility of makers will no doubt confirm

the experiences of many power users who have discovered anything up to

four or five different types in the comparatively narrow confines of their

homes or flats.

After examining and testing every variety, the association decided

that the "three-pin flat pin" type of 10 ampere capacity was most suitable.

Its advantages are positive contact, giving consistent efficiency and a

high degree of safety (the third pin being an earth connection). Accordingly,

this plug has been recommended to the Standards Association of Australia

by the New South Wales trade body. The electrical traders of Victoria and

South Australia are also in agreement, and have endorsed the recommendations.

The future should therefore see an alleviation of a state of affairs

that restricts the use of electrical utilities to one or two rooms. The

expedient of a sort of a universal adaptor comprising a fitting of each

kind may be evolved by the family handy man, but there is a great element

of danger in such a contraption, and it will sooner or later cause havoc

with fuses."

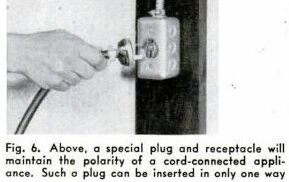

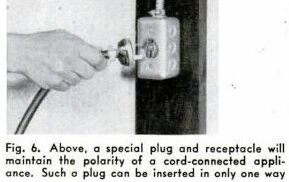

Taken from Popular Science in 1942, this shows the 3 flat pin plug

still in use in the U.S. Note the polarity is the reverse of that used

in Australia.

The U.S. design, which had been largely

promoted by General Electric, was officially adopted in 1938 by the Australian

Standards. It is curious that some articles on the subject claim the design

is "similar" to that of the U.S. From all the examples I have seen, some

actually in my collection, it is the same.

Safety Features.

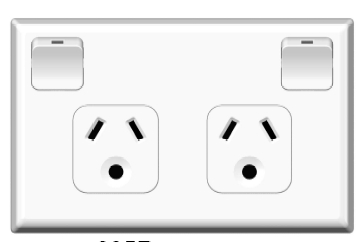

Some power points in Australia have had

shutters from time to time, but they are not compulsory. A particularly

problematic type of shutter arrangement is used in some 1950's/60's sockets.

It is actuated by the earth pin of the plug being inserted, and then uncovers

the live and neutral connections. The problem came about when two pin plugs

started to appear in the 1960's. One would have to insert something into

the earth pin before inserting the plug, plug in via a 3 pin double adaptor,

or simply dismantle the power point and remove the shutters. Soon after,

power points relied only on the neutral pin being inserted which took care

of the problem. While one could still insert something into the neutral

pin, polarity had now been standardised so there would be minimal shock

hazard.

Power points in portable applications

like caravans have (or should have) double pole switching in case they

are used with extension cords wired with wrong polarity.

A further attempt at improving safety

came in the late 1990's where proposals were made to recess sockets (as

common in Europe). This was unpopular because of the multitude of existing

plugs and plugpack transformers which would not fit into recessed sockets.

However, extension cord sockets fitted with a shroud did appear. Come 2005,

an alternative safety measure was introduced where plug pins were required

to be insulated at the plug body end.

This shows the difference in pin length before and after the standard

was officially adopted. The plug at the left is a very early Clipsal with

the same dimensions as the American plug, while the modern plug on the

right has shorter pin lengths as specified in the 1938 standard. The old

plug still goes all the way into a modern socket.

Elsewhere.

New Zealand also adopted the American

design with apparently greater initial enthusiasm than Australia. There,

the two pin polarised "T plug" had also been adopted, for 230V, along with

the three pin and two parallel pin designs. The same U.S wall box dimensions

were adopted, as in Australia, but the power points were mounted vertically,

as in the U.S.

An interesting question is who was first

in using the American plugs and wallboxes; Australia or NZ, and did one

country influence the other in adopting it, or was it just coincidence?

It does seem from my experience with vintage electrical equipment, that

Australia and NZ largely did their own thing independently of each other.

For some years now, NZ and Australia have had joint wiring rules, so wiring

practices are much the same in both countries, with some some local exceptions.

Because of the Australian and NZ influence

in the region, the plug design is standard throughout Commonwealth areas

of the South Pacific.

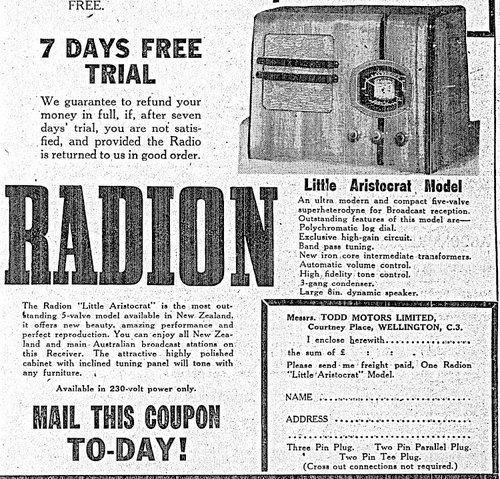

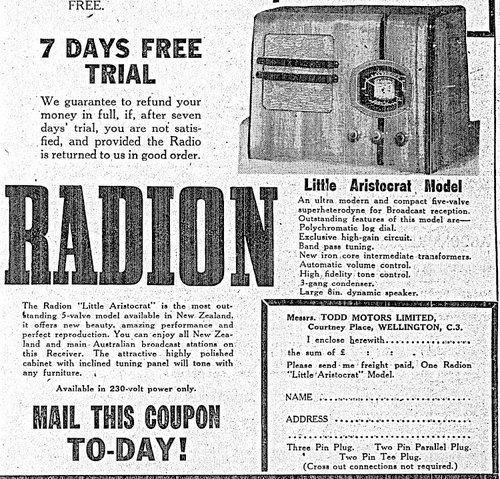

This advertisement from 1939 mentions the three types of American

plug in common use in New Zealand.

Argentina also adopted the American

plug, (presumably because of the proximity to the U.S) but the live and

neutral connections are reversed to that used elsewhere. Probably this

is because they have simply used the U.S configuration where neutral is

on the left when the earth pin faces down (see Fig. 7 in the above photo).

The plug design is classified under the IRAM 2073 standard. Because of

the polarity difference, power leads and accessories for the Argentine

market thus cannot be sold in Australasia and vice versa. In reality, someone

travelling between Australia and Argentina wouldn't have any problems.

Properly designed appliances should accommodate the possibility of transposed

neutral and live connections. I have come across one IEC lead that tested

reverse polarity; probably one for the Argentine market that found its

way in to Australia. A halogen light transformer was also found to have

the brown and blue wires reversed in the moulded plug.

Argentine power point. Although this one is switched, this does

not seem to be mandatory.

China is a late adopter of this

plug design. It would be virtually impossible to find any information on

when and why it was adopted. However, Chinese power points also allow the

plugging in of two pin American and two pin European plugs. Unlike Australia

and NZ, they are unswitched and the socket appears upside down to the normal

convention. Presumably, the reasoning of having the earth pin at the top

is that any objects falling in between a partially withdrawn plug will

touch the earth and not the live pin.

Papua New Guinea was a territory

of Australia until 1975, so naturally it adopted Australian wiring practices.

Other Pacific islands such as Pitcairn

Island, Fiji, Vanuatu, Tonga, etc. use the Australian/NZ wiring practices

simply because the materials are imported from these countries.

Polarity not standardised.

It may surprise the younger generation

that there was in fact no official polarity designation to start with.

After all, AC has no polarity, so an appliance will work connected either

way round. In fact, until the 1960's most plugs were not even labelled

as to which way round the live (otherwise known as "active", "line", or

"phase" ) and neutral connections should be; only the earth pin was designated.

Not only that, there was a common design of double adaptor which reversed

the polarity of one socket (easy to make it this way). Appliances from

the 1950's wired in the factory with the red and black wires transposed

in the plug are not uncommon. With a history of using bayonet light sockets,

and two pin English and American plugs it was assumed that appliances could

be connected either way round. It is for this reason that double pole switches

were often fitted to appliances. Certainly, switched light sockets as used

with desk or standard lamps always had a double pole switch. Even in the

1970's, I remember being told numerous times, "it doesn't matter which

way you connect the top two pins".

At this point one may query how a power

point could be wired with "wrong" polarity, when looking at a modern power

point the terminals are labelled and even colour coded. No one in

their right mind would connect it with live and neutral reversed. For one

thing, the neutral would be switched instead of the live which is an obvious

safety hazard.

Actually, it wasn't that bad. The first

generation of power points had separate switches and sockets; they were

not a complete assembly with switch integral to the socket.

That the live was switched was mandatory,

but how the socket was connected after the switch was not standardised.

So, if the switch was off the appliance was dead with either connection.

However, there was a "recommended" standard

which eventually became official (late 60's -70's?). This stated that looking

at the socket the top pin on the left was live. An easy way to remember

this is that a modern single GPO has the switch on the left and is thus

closest to the live pin.

It is more than probable that Australia

& NZ adopted the "live on the left" convention because of the switch

being mounted on the left. One could assume that with most people being

right handed, it is more natural to insert the plug with the right hand,

leaving the left to operate the switch. In the U.S. where sockets are not

generally switched this would have been irrelevant.

The 1950's Ring Grip plug on the left has no live and neutral polarity

markings, unlike the 1970's HPM on the right.

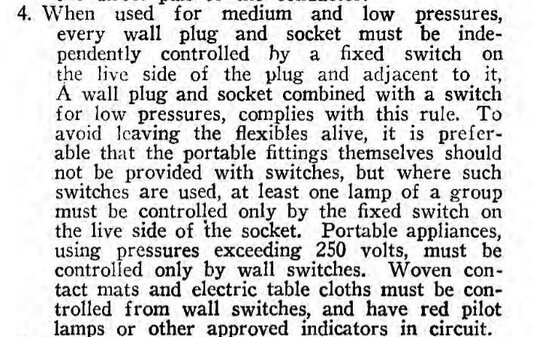

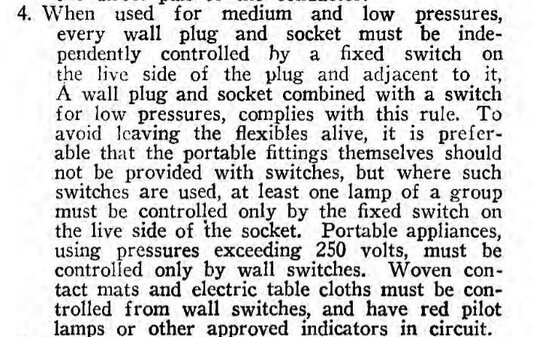

Switched Sockets.

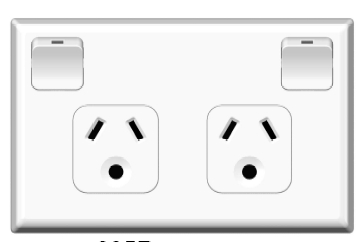

As to why Australian sockets are always

switched, early documentation notes that flexible cords were a not uncommon

cause of fire and other faults. Therefore, it was safer to switch off the

appliance prior to the flexible cord, rather than leaving it live when

not in use. The following extract is from the 1926 wiring regulations.

Not always earthed.

Back in 1979, I took the cover off an

ancient porcelain socket in a house that must have been wired in the late

1920's - early 30's, and was rather surprised to see no earth wire had

been connected to the socket. It was a typical power point of the era,

switch and socket mounted on a 6" x 3" wooden block. In fact, it was probably

the first generation of the three flat pin socket used in Australia. I

find it quite amusing when people discover such things today and almost

go into convulsive shock wondering how someone could wire the power points

in a house in such a seemingly dangerous manner. Not only were power

points wired like that by electricians, but it was permitted in the wiring

rules. However, there was a condition to this, and that was a power point

only had to be earthed if there were other earthed objects in the room

within a certain distance of the power point. Hence, a power point in a

bedroom might not be earthed, but one in a kitchen would be. This is not

as dangerous as it may seem. Providing there are no other earthed objects

within reach and the appliance becomes live then a shock will not be received.

Think about it; a bedroom with wooden floors and walls is a good insulator.

Unless you can complete the circuit to earth you're not going to get a

shock.

It appears this was allowed into the 1950's

and possibly early 60's by which time it was compulsory to earth all sockets.

It was only in the 1970's that an earth

had to be run to all light sockets in a house.

A collection of accessories to horrify the Nanny State control freaks;

at the top is a typical home made extension lead with figure eight cable

and thus no earth. At bottom left is a bayonet to three pin socket adaptor

useful for powering appliances where only a light socket is available.

It also has no provision for earthing. The double adaptor is of a type

that reverses live and neutral polarity on one of its outlets. Used in

the right situation these items are actually perfectly safe.

American wall box dimensions adopted

in Australia.

It may also surprise some that it wasn't

just the three pin socket we adopted from the U.S, but also their wall

box dimensions. Not only are the switch plate dimensions the same, but

even the screws to secure the switch or socket into the wall box have the

same thread (6-32). It is possible to install an Australian fitting into

a U.S wall box and vice versa. Until the late 1940's, power points and

switches were usually mounted on wooden blocks. This, along with split

seam steel conduit, was a legacy of British methods. While surface mounted

fittings and wooden mounting blocks were still being installed later than

this, in many post war homes flush mount switches and power points were

being installed. These, like their U.S counterparts, consisted of the actual

switch and or socket with a separate cover plate. As the switch and socket

were still separate units, albeit behind a common cover plate, polarity

of the socket was still not guaranteed. As an example, I work in

a building from 1956 and there is a GPO above an adjacent desk with what

would now be considered wrong polarity. By the 1960's power points and

light switches were being made with the mechanisms and switchplates being

one unit.

On the subject of wallboxes, in Australasia

these are enclosed only for brick or concrete walls. For hollow walls plaster

or stud mount brackets are used which are not enclosed. Mounting blocks

are also open at the back. Elsewhere in the world, it seems the backs of

fittings are always enclosed regardless of the mounting surface.

Australian made (Clipsal) wall boxes are of the same dimensions

and use the same 6-32 screws as the U.S. counterpart.

The M.E.N (Multiple Earth Neutral) system

of earthing is another Americanism we adopted. Here the neutral is connected

to earth at the switchboard. The reasoning is that if the earth connection

to the water pipe or earth rod has high resistance, the fuse will still

blow if there is a live to earth short. However, the downside to this is

that if the neutral connection fails, and the earth connection is high

resistance or non existent, then the earth wire and all that is connected

to it could rise up to 240V. What we did not adopt was the American colour

code, instead always sticking to the British with red for live and black

for neutral. Australians ignorant of U.S wiring practices invariably connect

the black to neutral and white to live when presented with an American

power lead, whereas it should be the other way round.

Orientation.

Even though we adopted the U.S style wall

box size, one area of departure was that unlike in the U.S, power points

were mounted horizontally. As to whether the earth pin was up or down was

another thing. Usually it has always been down, but some manufacturers

such as Clipsal for a while had it at the top. HPM during the 50's and

60's had it in between; with the socket turned at 90 degrees from the normal

position. Horizontal mounting of power points was not common in NZ; instead

they kept to US practice and most power points there are mounted vertically.

For some time now, the official orientation

of the earth pin has been at the bottom. The reasoning behind this was

that if a plug should be partially withdrawn from a socket, and hanging

down, the earth pin would still be making contact, even if the live and

neutral were not. The opposing point of view as implemented in some other

countries, notably the UK, is that the earth should be uppermost because

if the plug is partially withdrawn and an object falls down into the gap

(venetian blinds are one recorded example), it will not become live.

These HPM power points show that the earth pin wasn't always on

the bottom. The American style switch and socket is from 1956. As the switch

and socket are separate items the socket can be wired with either polarity.

In the middle is a late 1940's GPO mounted on a 6 to 240V shaver inverter.

This orientation is used today with the Chinese socket. To the bottom left

of this can be seen part of a bayonet socket which indicates this form

of power connection was still being used. To the right is a GPO from 1967

when HPM was experimenting with a design that suited both horizontal and

vertical mounting. Note these all have switches; Australia was the probably

the first country to mandate switches on GPO's.

Voltage.

It is often asked why there have been

so many different mains voltages. The answer to this is essentially one

of development and politics. The first reticulated power system, implemented

by Edison, was 110V DC. Given the prevalence of arc lamps at the time,

this voltage suited two in series. Also, lamp making technology being as

primitive as it was at the time, had a hard time making reliable lamps

for higher voltages. However, as is well documented, a simple 110V reticulation

system was very limited. For any given power, the current is doubled if

the voltage is halved. The problem then, is that the line losses are actually

squared. An improvement can be made by implementing a three wire system

where two 110V supplies are in series, giving 220V, and the common connection

is neutral. Provided the current drawn on both supplies is close to equal,

little current flows through the neutral, and transmission losses are reduced.

This is the scheme which has been in used by the U.S for a very long time

now, except of course the supply voltage has since been standardised at

240/120V 60 cycles. However, the current per 120V branch of the circuit

is still limited. This leads to the situation where domestic appliances

that draw more than 15A (1800W) require a special 240V socket.

In Europe, there was a mixture of 110V,

127V and 220V operating at 50 cycles or in a few instances, DC. If 127V

seems a little odd, it's the phase to neutral voltage of a 220V three phase

supply. However, 220V single phase/380V three phase was soon adopted as

the standard, and the lower voltage systems phased out. It appears that

Siemens in Germany had done much to promote the 220/380V system with its

advantages over the lower voltage systems.

In Britain with a very localised power

generation and distribution system, there was little standard. Anything

from 100V DC to 250V AC could be found. And the AC wasn't always 50c/s!

Again, it would depend on who built the generating equipment as to what

the voltage and frequency would be - each no doubt being "the best" in

the eyes of its beholder.

That all changed with the commencement

of the National Grid in the 1920's; the completion of which would implement

a nationwide frequency of 50 cycles, and a standard residential voltage

of 230V. It was intended that not only would the UK use 230V, but so would

the rest of the British Empire. This didn't quite happen with each country

going their separate ways as time went on. In 1946, the UK standard was

changed to 240V.

In Australia.

It was hardly surprising that Australia

followed British practice and chose 210-250V for the single phase residential

supply, thereby avoiding the voltage drop, the requirement for heavy gauge

wiring, and limited current availability inherent with the 110-120V system.

Two or three phase supply (415V between phases) to homes is quite common

in Australia. Apart from increasing efficiency in all electric homes, it

is used on a domestic level for some instantaneous water heaters, and some

workshop equipment. Australian made electric ranges allow for a two phase

supply where this, or a three phase supply, is available.

What has been standardised at 240V 50

cycles per second for many years in Australia was not always so. Generally,

New South Wales, Tasmania and Queensland standardised on 240V 50c/s and

Victoria on 230V 50c/s. Heading west, 210V 50c/s had been used in South

Australia, and 250V at both 40 and 50c/s in Western Australia was used.

There were two large towns using 110V; Launceston and Broken Hill. Away

from the capital cities there was more variation, with DC being used in

some towns (220-250V). The reason W.A. was the odd one out with regards

to frequency, is that the 40c/s generating plant was imported from South

Africa. DC mains was used in Sydney around the northern part of the CBD

until the mid 1980's, but by that time remaining only for lift motors.

The rest of the supply had been converted to AC by the 1950's. By the 1950's

plans were afoot to standardise Australia on 230V 50 cycles in line with

the Empire and many localities went through the conversion process. 240V

areas were to be left as is, being within 10% of 230V. Probably because

the 240V areas outnumbered the others, this actually became the standard

instead.

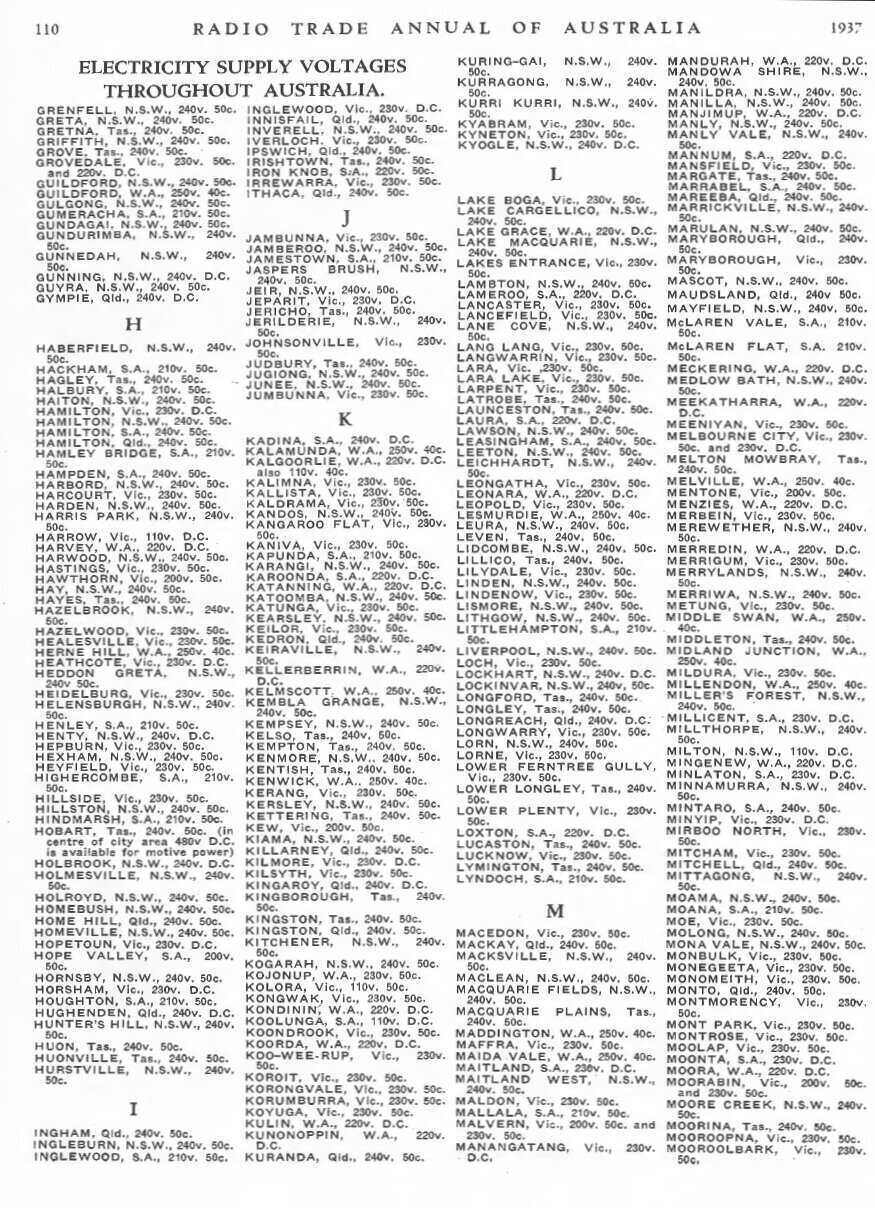

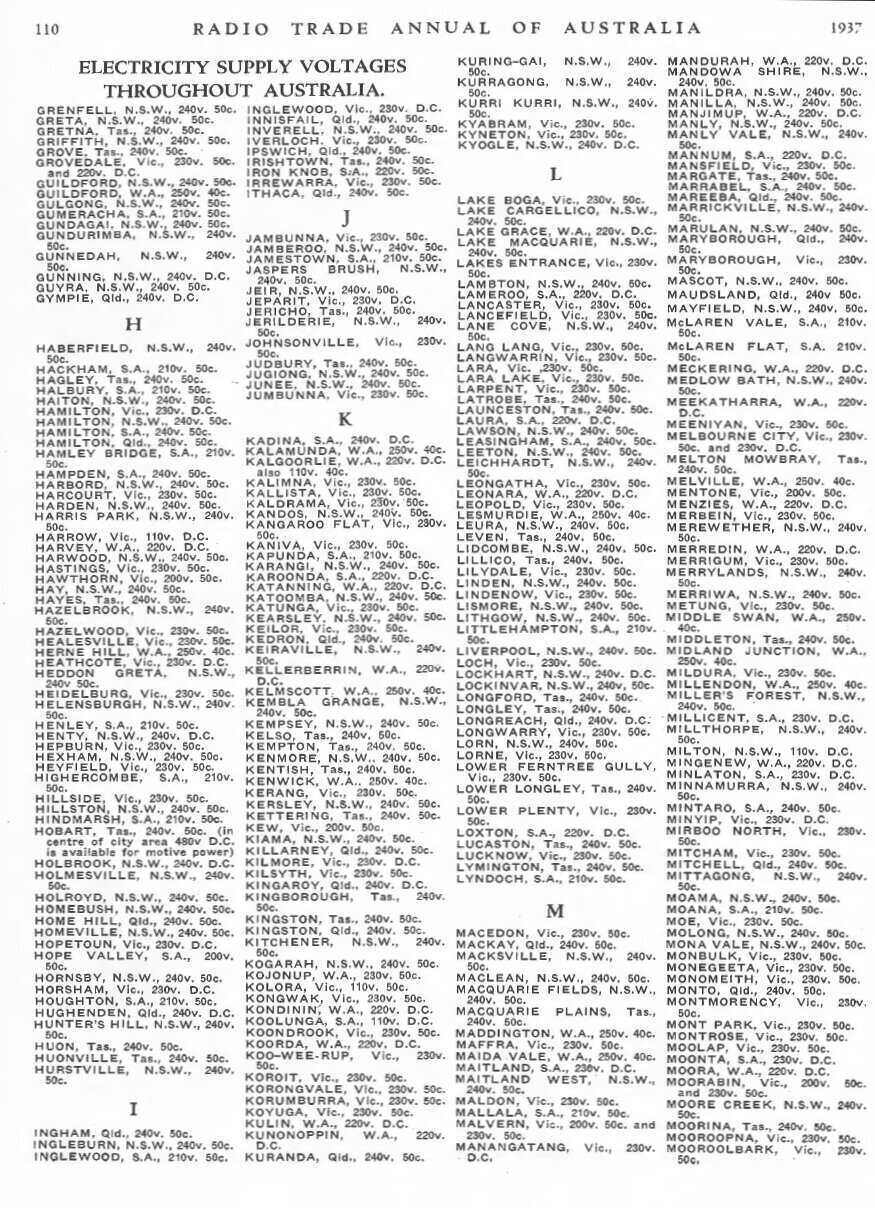

From the Radio Trade Annual, 1937, this shows the variation in mains

voltages throughout Australia.

Victoria changed to 240V in the early 1960's.

230V electricity meters are still visible on old houses there today. Adelaide

started to move away from its 210V supply in the 1950's and Western Australia

dropped to 240V in 1985.

If it seems like a huge excercise to convert

appliances to suit a new supply, it must be remembered that at the time,

houses had few appliances. In the 1950's, apart from incandescent lamps

in each room, there would be a toaster, jug, and cooking range, and a radio.

The more affluent would also have a refrigerator, washing machine,

and maybe a vacuum cleaner.

The lamps are not frequency dependent,

so they can be left in situ unless it's the voltage that's going to be

changed. Likwise, all the heating appliances. Should the new voltage be

markedly different, it was a simple matter to replace the elements, which

were all standard types. The radio might require a reset of the voltage

tapping on the power transformer but that would be all, unless it was part

of a radiogram. There, the pulley on the turntable motor would have to

be replaced when changing from 40 to 50 cycles. The few AC/DC radios usually

needed no modification as they included a baretter to stabilise heater

current for the valves, and could accomodate a wide range of voltage.

In New Zealand.

New Zealand had standardised nationwide

on 230V right from the start, although in Wellington there was an unusual

105V 80c/s supply from a steam driven power station. With the disadvantages

of the low voltage supply becoming apparent, it was decided in the mid

1920's to change to the 230V standard. This was completed in the early

1930's, by which time the power source was hydro electric.

Australia and 230V.

Since 2000, the "official" standard for

Australian mains voltage is 230V. In a sense, this is deja vu for those

living in Victoria. However, this was really a case of Orwellian Newspeak

(i.e. calling something which it is not to be politically correct), because

the actual voltage was not changed from the nominal 240. The same situation

occurred in the UK, although a few years earlier. The scheme was proposed

in the 1980's by the IEC to standardise on two world voltages; 120V and

230V. This was supposedly to assist manufacturers to make electrical products

for a global market. The idea was that 240V and 220V countries would "harmonise"

(to use the politically correct term) their mains voltage. So, the UK and

Australia, for example, would drop their mains supply by 10 volts, and

Continental Europe would increase theirs by the same amount. In Australia,

in 1994, there was established a "230V Committee" to oversee this transition

locally. The perfect bureacratic situation could be imagined here with

much paper shuffling but nothing else.

In effect, nothing actually changed as

far as the consumer was concerned; all that was done was to reduce the

upper mains voltage limit by 6% instead of the previous 10%. So, the nominal

240V still falls well within that. One will note that incandescent lamps

(including halogen types), sold in Australia, are still rated at 240V to

reflect the truth of the situation. As summed up in one letter to the UK

magazine "Practical Electronics", some years ago, "it's only on paper".

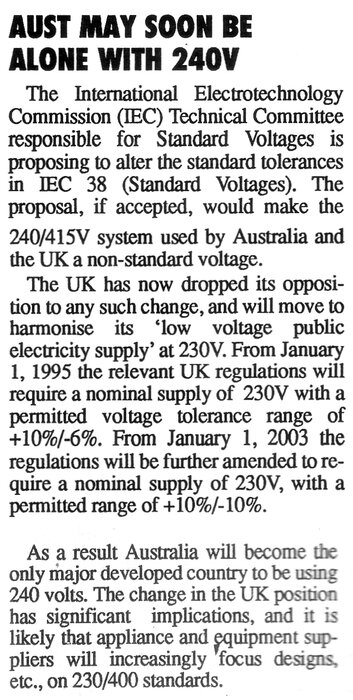

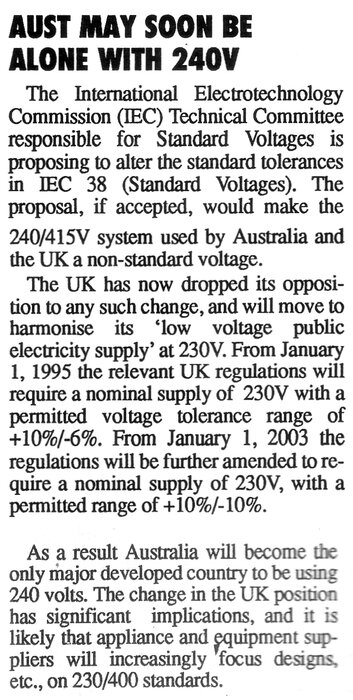

From Electronics Australia, July 1994. Of course, Australia never

really was going to be 'alone with 240V' - instead being very obedient

to dictatorial powers.

The IEC is also trying to implement two

worldwide standard plugs and sockets; one for 120V, which interestingly

remains as the U.S. NEMA 5-15 type (they probably realise that the U.S.

would probably ignore them), and another which replaces all the types currently

in use for 220-240V.

Other Plug and Socket Configurations:

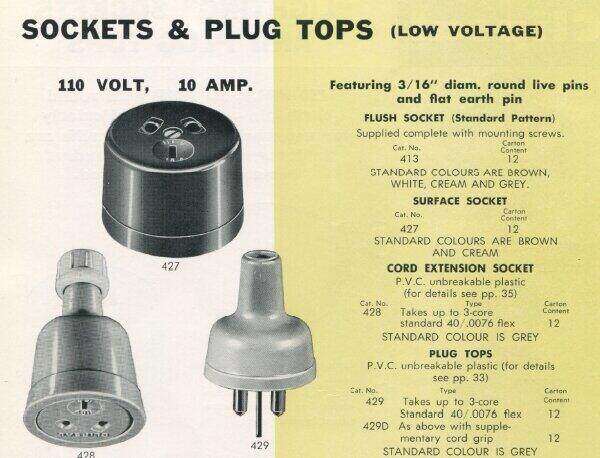

Extra Low Voltage and the "T" plug

& socket.

Rural homes not connected to any public

supply usually used 32V DC, but sometimes 12V, 48V, or 110V DC, from a

set of generator charged batteries. These would be charged from a stationary

engine or a wind generator. Another American socket had been adopted for

these extra low voltages known as a "T socket", but unfortunately many

simply used the three pin 240V type instead. Disastrous results awaited

appliances so fitted, when someone took them to another location and plugged

them into a 240V power point, unaware of the voltage. The two pin parallel

blade plug and socket has also been used for non polarised ELV applications,

particularly for 32V lead lamps. Although not ideal, it does prevent accidental

connection to 240V.

Socket used for extra low voltage supplies (up to 32V). Current

rating is 15A. It is recommended by Clipsal (the predominant manufacturer),

that where the supply is referenced to earth, the bottom pin should be

used for this.

We can see here the American origin of the Australian ELV socket.

However, in the U.S. it was intended for 120V use. NZ used it for

230V.

In the modern day, 32V DC systems only

exist in the hands of vintage technology enthusiasts, as appliances have

not been made for this voltage since the 1960's. Rural type off grid electrical

systems these days tend to be solar powered and use 12V DC for small systems.

Large systems are usually 240V AC, inverter powered from a 24V or 48V battery

bank.

The "T socket" (Clipsal 402/32) is nowadays

mainly used for 12V applications, such as in a solar powered house, or

for caravan, boat, and 4WD use. It also finds common use for portable lead

lights powered from 32V AC isolating transformers.

As mentioned previously, the "T" plug and

socket was used in NZ, but for 230V. At that time Australia and NZ had

their own wiring regulations independent of each other. It is not entirely

clear as to the present day status of this connector in NZ, as it is conceivable

there might be very old installations where sockets of this kind are still

connected to 230V. This would obviously be unacceptable where it is also

used for ELV.

Although not specific to Australia, for many years Toyota used the

U.S. style two pin plug and socket for their 12V car trouble lamps. One

can imagine many blown light bulbs in countries where that plug is standard

for mains voltage.

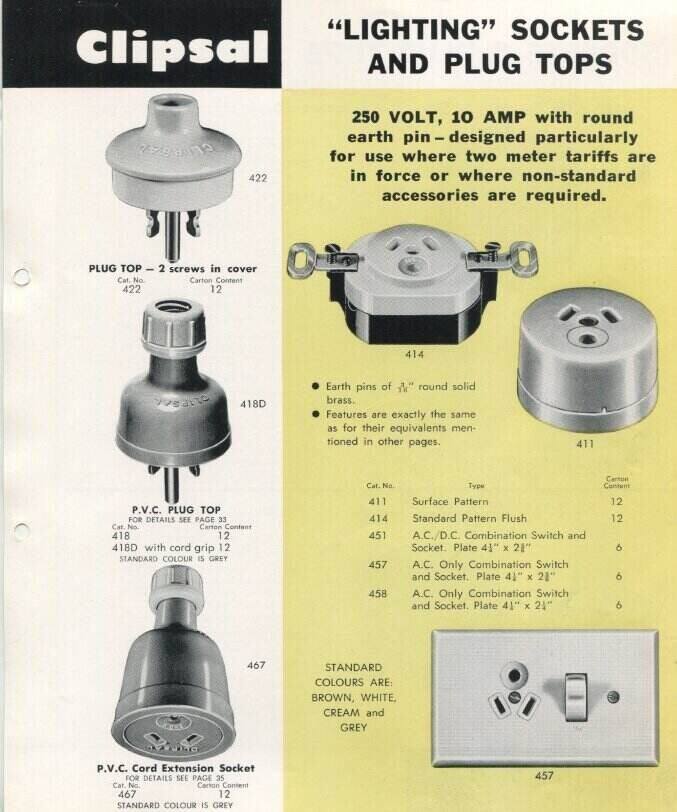

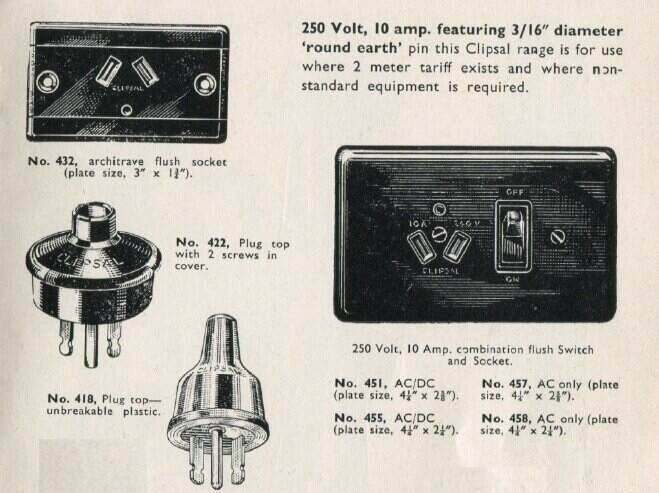

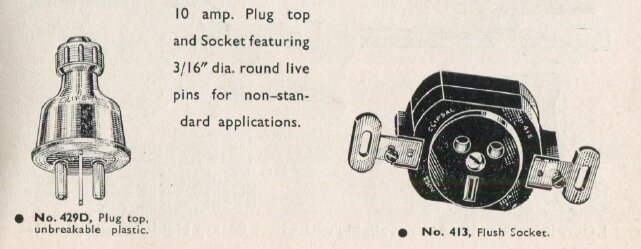

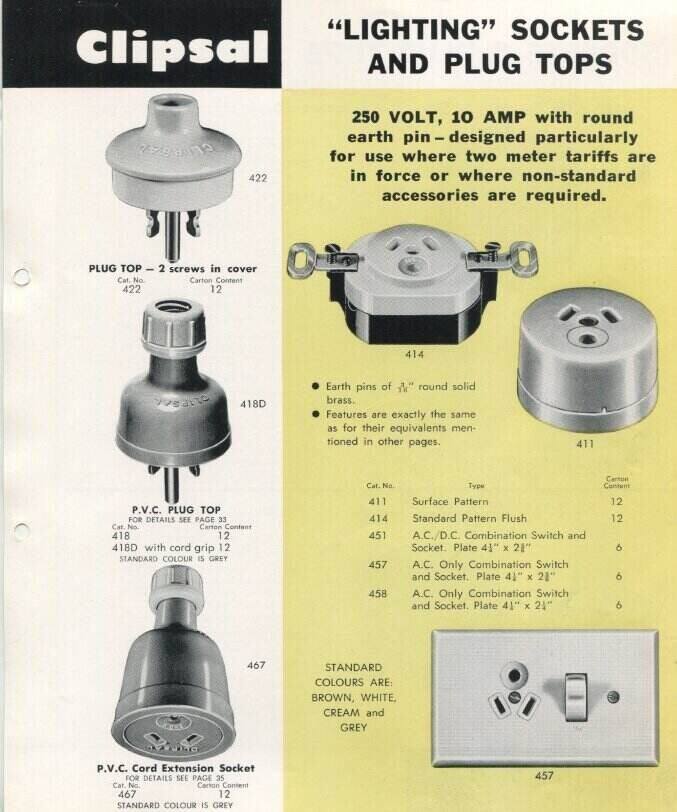

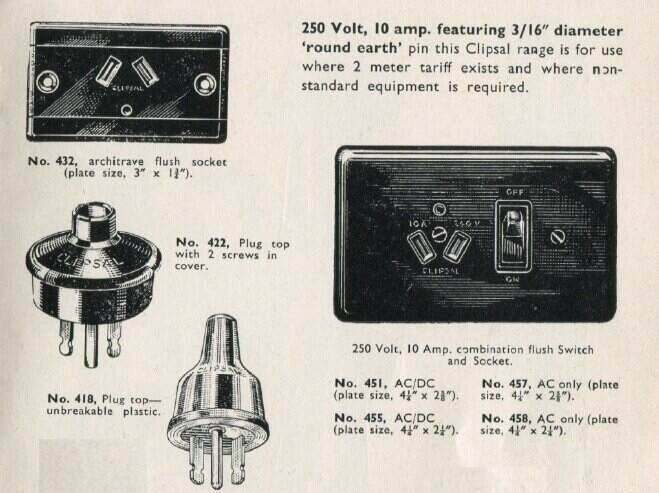

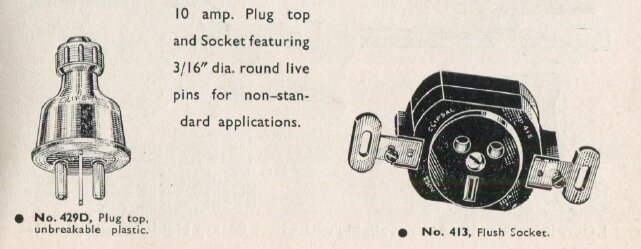

The Round Earth Pin plug and socket.

This was initially introduced for use

on lighting circuits. In some areas there was, once upon a time, two separate

tariffs for light and power circuits. The round earth configuration prevented

ordinary appliances being plugged into the cheaper lighting supply. Portable

lamps

would be fitted with a round earth plug.

It is hard to imagine how this scheme could be policed, when it would be

a simple matter to fit a round earth pin plug to any other appliance. Furthermore,

appliances were already being connected to light sockets via a bayonet

plug.

However, separate light and power tariffs

faded into obscurity, and the round earth configuration instead became

used for all kinds of "special" applications. For example, it has been

used to differentiate between circuits supplied by uninterruptable power

supplies, and the ordinary public supply. Other uses include connecting

remote switches (eg. switch for room light mounted in a bedside table).

Sometimes it is used for other voltages. Despite the existance of a standard

extra low voltage plug and socket, the round pin configuration has also

been used for this purpose. Essentially, it is used where compatibility

with the standard 240V connector is undesirable. With the increase

in appliances fitted with two pin plugs, the design is no longer as incompatible

as it once was. Therefore, the socket should not be fed with a voltage

or frequency that could damage a normal 240V AC appliance.

NEMA 7-15R socket. No doubt the source of Clipsal's inspiration

for the local product.

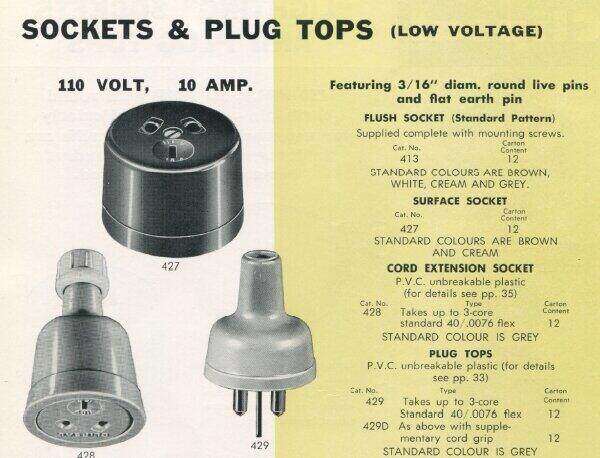

The 110V Plug and Socket.

Since the two flat parallel pin plug and

socket was already in use for 240V, Clipsal came up with a configuration

for 110V. When this plug and socket was introduced in 1961, it was intended

for "non standard" applications, but by 1962 became their 110V standard.

This configuration is unique to Australia,

and only manufactured by Clipsal. It is, ironically, the reverse of the

U.S. standard NEMA 5-15 configuration, where the earth pin is flat instead

of round, and the live and neutral pins are round instead of flat.

Once Upon a Time...

Because the American parallel flat pin non polarised plug has the

same pin dimensions and spacing as the Australian plug, it is possible

to simply twist the pins to enable insertion into an Australian socket.

This used to be commonly seen with imported or duty free bought items but

foreign manufacturers are now more aware of our requirements.

Until the 1980's it wasn't uncommon to

see two pin U.S. plugs being used in Australian power points as the above

photos show. This came about largely from Japanese electronic equipment

being sold in Australia from the 1960's onwards.

Overseas travellers would also bring back

appliances from foreign duty free stores. Because the pin dimensions and

spacing are the same, a simple twist with a pair of pliers will enable

the two pin plug to fit.

It is also handy to know that European

plugs will fit into a standard appliance cord as used with old electric

jugs and toasters. However, this should only be done where no earth connection

is required.

As regulations were tightened, all appliances

sold in Australia must now be compliant with Australian Standards.

Home