Later style label and box design.

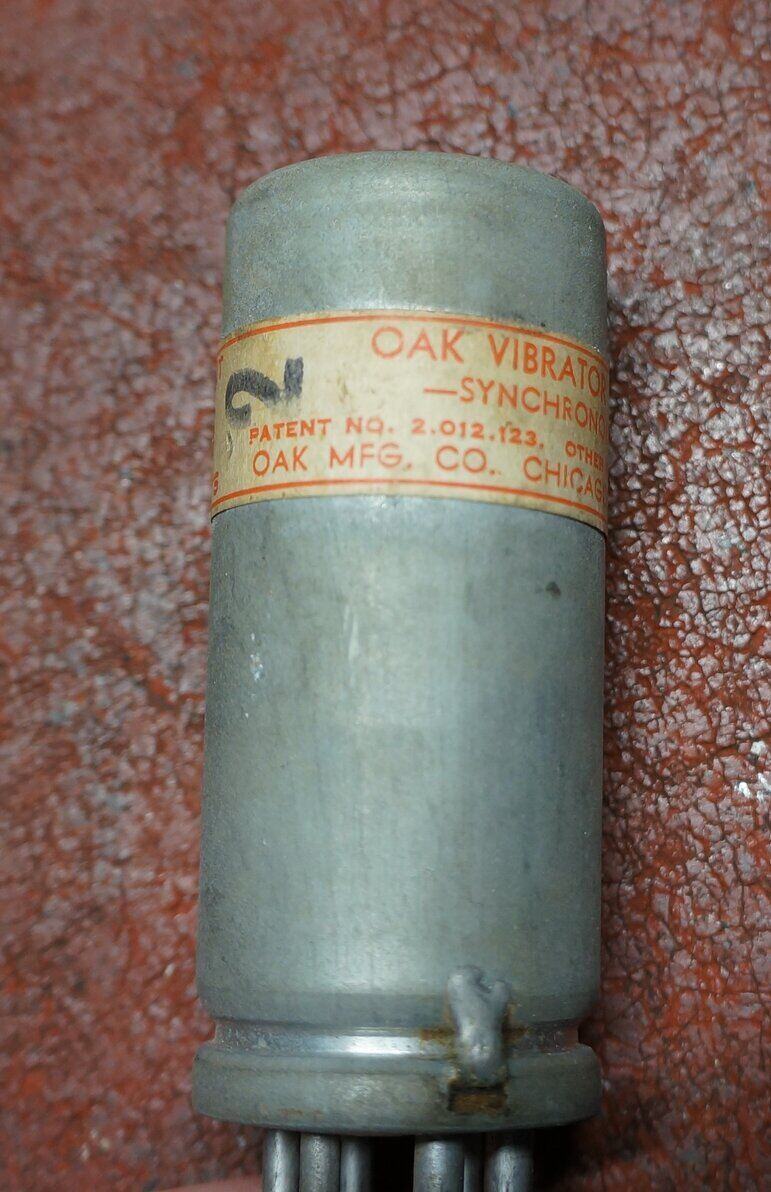

The most popular vibrator in Australia was the MSP/Oak/AWA unit. It was exclusively used by numerous manufacturers including Ferris, Philips, Ferguson, Aegis, and of course, AWA. In fact, it was used by most manufacturers except for Astor, Air Chief, and other Electronics Industries brands, who used their Ferrocart branded vibrator. The other common Australian vibrator type was Van Ruyten, but these are high power 50 c/s units used for 240V AC inverters, and appear to have been made by Electronic Industries. Aside from these, foreign brands are sometimes seen, particularly in imported items.

Later style label and box design.

Oak Vibrators in Australia.

AWA was manufacturing vibrators in Australia,

under licence to Oak in the U.S. Initially, the vibrators were branded

AWA, but later branded MSP. "Manufacturers Special Products" was the component

manufacturing division of AWA which came into being after WW2. It was a

way to sell AWA components to competing manufacturers, as MSP was not a

brand name associated with consumer products. It can be imagined, for example,

that an AWA vibrator inside a Philips radio would look awkward from a commercial

point of view. The AWA manufactured version was based on the 1934

design, and unlike in the U.S., did not change until the cessation of vibrator

manufacturing around 1973. Oak types in the U.S. had several can styles,

many of which were crimped closed. Fortunately, AWA kept the can design

to the original type, with the mechanism secured inside by a spring clip

around the base. This makes subsequent servicing, if ever required, very

simple.

AWA's first car radio (model 74) in 1934

used an RCA vibrator, which was the same type used in the RCA M34 car radio.

The next AWA car radio model, the 153 from 1935, used a motor-generator.

A return to vibrator power supplies was coincident with the 401 in 1937.

However, it is not until the model 404

of 1938 that the service manual acknowledges that the Oak vibrator was

available as a replacement. The original vibrator for the 404 was an Electronic

type (Electronic

Laboratories). This is a shunt drive type and the manual describes

rewiring the vibrator socket to take the Oak replacement. From this, it

seems that the Oak vibrator was standard in Australia by 1939.

Prior to MSP coming into existance, original production was labelled

AWA.

Apart from types V5105 and V5124, most Australian type numbers are not used by Oak in the U.S. and vice versa. AWA also did local development of the design. At the time, there was little demand for 12V vibrators in the U.S., and so it fell on AWA to provide 12V types for the multitude of English cars in Australia. Likewise, the 4 volt types for domestic sets were not common in the U.S. A patent taken out by AWA relates to the development of the split-reed type. A method of driving 6 volt dual-interrupter vibrators off either 6 or 12V without changing the vibrator or transformer is another AWA patent.

24 and 32V types were not manufactured until after WW2. Earlier 32V radios are shown with a 12V V5258 synchronous vibrator operated with a 100 ohm resistor in series with the drive coil. By 1950, a 24V type was available, and was being used in at least one Radio & Hobbies project on 32V, again with a drive coil dropping resistor. It appears that 32V types became available shortly after.

At left is the first generation of MSP labelling, and at right is

the early style box.

From notes in Radio Engineering, April 1935. Their prophecy of longevity

turned out to be correct.

It is because of the prevalence of the

Oak design in Australia, that reliability problems which seem so common

in the U.S. where the shunt drive type is standard, did not exist here.

To help explain this, it must also be pointed out that in the era of vibrator

powered equipment, that timing (buffer) capacitors were usually paper types

with relatively poor reliability. This has more than likely contributed

to the common "vibrators are unreliable" myth that exists. With a

poorly performing timing circuit, the power contacts will wear quickly,

and then the vibrator will not start. In the same circumstances, the power

contacts of a separate drive vibrator will also wear, but the reed will

still vibrate as normal. The effect is that the output voltage of the power

supply is still present, but gradually drops due to the descreasing duty

cycle as the contact gap increases. So, under less than ideal conditions

the vibrator is still "working". Of course, with the correct loading and

operating conditions which avoid contact wear, the shunt drive type will

also have good reliability, provided the vibrator is of reputable design

and manufacture. Obviously a non-starting vibrator is more of an inconvenience

than one which simply has reduced output, and in this regard the separate

drive is ultimately more reliable.

Out of my hundred odd items of vibrator

power equipment, it has never been necessary to actually replace a vibrator

(shunt or separate drive); and this is over more than 35 years.

So, fear not fellow Aussies; do not take

what you read in overseas magazines and vintage radio forums as gospel,

regarding vibrator reliability. Our separate drive MSP/Oak units do not

have those issues, instead lasting as long as any other electronic component.

And, if you're into restoring Astor/Air Chief car radios, it's worth looking

out for the Oak replacements for the original Ferrocart types. These are

discussed further on.

Of course, it's important to note that

unsuitable circuit design, loading, or defective timing capacitors will

ruin even the best vibrator. With the correct component selection and attention

to power rating, an Oak vibrator is completely reliable with an extremely

long life - so long that it's really a non issue.

Similar release notes From "Electronics", May 1935.

Unfortunately, vibrators often fall victim

to the incessant 'tweaker' who is drawn to its moving parts like moths

to a light. Oblivious to the precision construction and careful setting

up in the factory , they twist the contacts this way and that, attempting

to repair a defective unit. The teeth marks of long nose pliers can often

be seen...

In actual fact, randomly "adjusting" a

vibrator is one of the worst things one can do. One needs an oscilloscope

to do it properly, for the timing and duty cycle cannot be accurately set

otherwise. Unfortunately, some enthusiasts cannot get past the "it's just

a buzzer" mentality.

Run into a resistive load, the vibrator primary contacts are adjusted

thus. A tweaker who jumps in with a pair of pliers and no instruments cannot

hope to duplicate this. Add secondary contacts and the mess can be imagined!

Yet, they're the first to complain about the reliability of vibrators...

Operation at Higher Voltage.

Another advantage of the separate connection

to the driving reed is that it is possible to operate the vibrator off

a higher voltage, simply by connecting a resistor in series with the driving

coil. For example, a V5105 which has a 6V coil can be run off 12V with

a 22 to 27R 5W resistor in series. One model of Philips car radio, NT364V,

had this facility built in, so that the radio could be used in a 6 or 12V

car simply by changing links under a panel. The power supply shown below

operates a 12V vibrator from a 32V supply using a 100R 3W resistor in series

with the drive coil.

32V vibrator power supply for an AWA domestic radio. When this was

designed, 12V was the highest voltage available for the vibrator. Note

R1 to drop the coil voltage. Once 32V vibrators became available, R1 was

deleted. Incidentally, this power supply was issued with a modification

to move the timing capacitance to the primary, to eliminate contact arcing.

The Bland shaver inverter is another example; in this case a 6V vibrator is used on 12V.

Construction of the Oak vibrator.

The design of the driving coil is unique

to Oak and was one of their patents. It will be noted on most schematic

diagrams that the Oak vibrator has a secondary winding on the driving coil

which is short circuited. This is wound with chromoxide resistance wire

and considerably lowers the Q of the driving coil. The windings are

bifilar wound. The purpose of this is to eliminate sparking at the driver

contact. It does this because the lowered Q slows down the rate at which

the magnetic flux collapses when the contact opens. The usual inductive

kick back is prevented. Other manufacturers of separate drive vibrators

use more conventional spark suppression circuits with a resistor, a capacitor,

or a combination of both.

The reed is made of Swedish spring steel.

The power contacts are made of Oakalite tungsten, and the drive contact

is palladium silver alloy. The can is usually zinc, but a small proportion

were made with aluminium. The vibrator mechanism is secured to the can

by a spring clip, and is earthed to one of the pins.

Servicing.

As with most vibrators taken out of storage

after many years, the insulating film that builds up on the contacts needs

to be cleaned off. This is usually the cause of a vibrator not providing

output, whether it starts or not. The driving coil contact seldom is affected

this way, because it is made of a precious metal and does not tarnish.

It is also normally closed, and thus nothing gets in between the contacts

when not in use. Mallory mentions that the film is tungsten oxide which

forms on power contacts. However, it seems to be more prevalent in vibrators

where sponge rubber is used inside the can. In this case it appears to

be a decomposition by-product (sulphur is one possibility). The film can

be physically cleaned off the contacts by means of 600 grade sandpaper

or a fine blade such as an X-acto knife. However, care must be taken not

to upset the contact spacing. For this reason, I prefer to electrically

clean the contacts where the film build up is fairly minor. Current limited

high voltage will break through the insulation and burn it off.

Another sensible aspect of design is that

service access for the Australian Oak vibrator is easy. Unsolder the earth

tag and remove the spring clip. The mechanism can then be slid out. In

some instances, it will be found the base of the can has expanded in diameter,

with the phenolic base a looser fit than normal. This is a result of the

constant pressure from the spring clip against the soft zinc can. The zinc

creeps over time under pressure.

Usually, it is not necessary to open the

vibrator unless it has been damaged, or after a long period the contacts

in a synchronous or dual interrupter type need to be retimed.

If the driving coil does not function

it's either: 1) the wire broken off just near the coil, 2) the adjustment

screw for the contact is a bit out, 3) dry joint in pin or at bottom of

vibrator frame. In a couple of rare instances broken or cracked reeds have

been found, and in one, the foam lining of the can had been replaced with

a type which decomposed rapidly, leaving a sticky substance between the

contacts.

To electrically clean the contacts, the following test jig can be assembled:

A battery of appropriate voltage is used

to get the reed vibrating. While a bench power supply can be used, there

is a risk of inadvertent damage if it should somehow come into contact

with the high voltage. High voltage is obtained from a 240V isolating transformer

and current limited to 400mA by a 100W incandescent light bulb. This is

applied to each contact in turn until the contaminants burn off. Obviously,

once this happens the bulb lights up. Because of the vibrator frequency

not being related to the mains supply, the bulb will flicker once the contacts

make. This is quite normal.

It goes without saying that no part of

the circuit, or the vibrator should be touched while the mains is connected.

The can of the Australian made Oak vibrator is usually connected to the

reed. Although the transformer provides isolation from the mains,

there is still 240V between its secondary terminals. A double wound (not

an autotransformer!) 240V to 120V stepdown transformer can also

be used for the same purpose if one is conveniently available. The voltage

is not critical.

Note that this method of contact cleaning

will only remove oxide. It will not restore pitted or misadjusted contacts.

Disclaimer:

No reponsibility is taken for undesirable results that occur from not using

an isolated supply, or other unsafe practices.

Check all contacts

It's important to see that all contacts

are functioning, because if the vibrator works in half wave, those contacts

which are working will be damaged. Simply observing the transformer

waveform will confirm this, but the output voltage is also revealing. A

potential problem is someone who gets a vintage radio, turns it on and

find that it appears to work. If the vibrator is working in half wave,

the radio will indeed be working, deluding the owner into thinking all

is well. However, damage will soon set in, and if the contacts are badly

burned and the spring temper damaged, the long term reliability could be

poor despite efforts to repair the vibrator.

Adjustment of the Oak vibrator.

Discussion with a retired AWA employee

who worked in the vibrator division of MSP brought forth some useful information.

The vibrators were adjusted after assembly using a test panel fitted with

dwell meters and also a CRT. The vibrators were tested with a resistive

load. Apparently, this test panel was "ancient" and pre-war. The CRT was

assumed to be a 5BP1. The adjustment was done only via the side (fixed)

contacts. As it happened, the precision of manufacture was that not much

adjustment was needed anyway. A standard type of relay adjusting tool was

used; i.e. a rod with a slot cut into the end. Each primary contact was

set up for 40% duty cycle with a 5% tolerance. When operating in a full

wave circuit, the duty cycle is therefore 80%.

Because the Oak vibrator operates at 100c/s,

this means each contact is set for 4ms closing time. With a calibrated

oscilloscope, the adjustment is therefore quite easy. While I could have

designed my vibrator

test panel with dwell meters, it's more accurate to use a CRO, which

these days are inexpensive and commonplace anyway. Further detail on adjustment

is given here.

Setup for adjustment by meter.

The setup for adjustment by dwell meter

is shown above. The variable resistor is adjusted so that the 1mA meter

shows full scale deflection when the meter is connected directly to the

battery negative (or the vibrator contact held closed).. By this means,

it can be seen that when the vibrator is operating, the less than 100%

duty cycle will show up as a reading less than 1mA. The vibrator is then

put into operation, and the readings observed. Adjustment is for the primary

contacts to show 40% of full scale, and the secondary contacts to show

38%. Note that this method of adjustment has some limitations. It is suitable

only for separate drive vibrators such as the Oak. The figures given suit

the Oak vibrator, which has a lesser duty cycle than some other types.

Nevertheless, the scheme could be used for other types if a known good

sample can be compared with. Obviously, the meter used must have good accuracy

to show the 2% difference between the primary and secondary contact duty

cycle.

This method also relies on the contacts

being in excellent condition (it was intended for new vibrators during

manufacture). If the contacts are dirty, the time they actually make contact

may be less than the physical time they are touching. Adjusting a vibrator

with less than excellent contacts this way is likely to result in error.

This method is shown as an alternative if a vibrator must be adjusted in

the absence of a CRO, but is not ordinarily recommended.

Run into a resistive load, the contacts show provide a waveform

like this. 3.88ms is within tolerance.

To obtain the correct duty cycle entails carefully bending the arms of the fixed contacts, with a narrower spacing obviously increasing the duty cycle. The vibrator primary contact adjustments have a 5% tolerance at 40% duty cycle for each contact. This means 3.8 to 4.2ms is acceptable. The above waveform was taken using the vibrator test panel which uses 8R 20W resistors for the load. The resistor values are not critical, but should provide around 500mA to 2A current flow to ensure the contacts are 'wetted'. The vibrator used for this example is from the Walbar car radio.

The same setup is used for the secondary

contacts in the case of synchronous vibrators, but instead of 4ms, the

'on' time needs to be 2% less; i.e. 3.8ms. Obviously, if the primary contacts

happen to be set at 3.9ms (such as in the above photo), then the secondary

contacts should be 3.7ms. The secondary contacts must always close after

the primary contacts, and open before.

For split reed vibrators, adjust one set

of contacts as you would with a non-synchronous type. Then, using this

first set of contacts as a reference, adjust the other set so that the

timing is identical.

Non Synchronous types.

The basic vibrator, most commonly used

in car radios and small inverters. Where DC output is required, a valve

or other rectifier is required. Most commonly found are the V5105 and V5123

types. Since local manufacturing began, these were used in every AWA

car radio, of the valve rectifier type, up until the last model in 1966.

Note that with all the vibrators types listed (not just the non - synchronous

types), the contact current rating goes down as input voltage increases.

This is because arcing is more prone to occur with an increase in voltage.

Synchronous types.

These are fitted with secondary contacts

for self rectification. Commonly used where it is undesirable to use a

valve rectifier, such as where dictated by space or power consumption constraints.

Some car radios did use synchronous types, but mostly they were used for

accumulator powered domestic radios. Note that the timing of the primary

and secondary contacts is not identical. The secondary contacts open and

close slightly later than those of the primary. The 4 volt type might cause

some curiosity. It had two popular applications. One was for portable camera

flash units where a small two cell lead acid battery was used, but more

commonly they were used for 6 volt accumulator powered radios. Here, the

vibrator is connected across the 4 volt section, and the valve heaters

across the remaining cell (2V). The idea was that by supplying the directly

heated filaments from a separate cell, it was easier to keep modulation

hum from vibrator out of the system.

There was also an Oak synchronous type for operation from a 2V accumulator. This was used in the HMV model 62 power supply.

Synchronous Split Reed types.

These are mostly used in domestic accumulator

powered radios, because with directly heated battery valves an external

bias supply is often required. As the valves filaments are also the cathode,

it is not possible to use cathode bias in the same way as indirectly heated

types.

It is also possible to configure a split

reed vibrator so that it works as a full wave switch into a non centre

tapped transformer primary. The Bland shaver inverter takes this approach.

It is worth keeping this in mind where it is necessary to convert a 6V

car radio to run on 12V. By changing the vibrator to a split reed type,

it is possible to keep the original 6-0-6V transformer on 12V by not using

the centre tap.

AWA applied for a patent for their split reed vibrator in 1941. Certainly, outside of Australia, the split reed synchronous vibrator was less common. Mallory had a couple of types listed in 1936, but these were discontinued by 1945. Their preference was to instead use a "bias cell" for battery valve sets, to obtain negative bias.

A 2V split reed synchronous type is shown in the circuits for several HMV radios including the 600, 601, and 161, and also the power supplies 61 and 62. It predates local manufacture, and would have been imported. No type number is given.6-12V conversion with a Split Reed

Vibrator.

Vintage cars having their 6V electrical

system converted to 12V are a fact of life, as much as the practice is

undesirable. When it comes to the radio, several options are available.

A 6 volt radio can be simply run from the new 12V supply by means of a

resistor. The resistor is selected so that with the battery 12V (i.e. not

charging), the radio receives 6V as measured on an analog meter. Why analog?

Because the current draw is not steady DC and the peculiar waveform is

more likely to give a less accurate result with a digital meter. In practice

the resistor value is somewhere around 2.5 ohms and dissipates a fair bit

of heat; 30W is not uncommon. The exact resistor of course depends on the

particular radio and has to be selected on test.

The disadvantage of this scheme is the

wasted power and that the nominal 6V changes as the radio warms up. This

may or may not be a problem in the particular situation.

The more efficient method is to convert

the radio to 12V. For the valve heaters and dial lamp, these can be replaced

with their 12V equivalent; e.g. 12X4, 12AQ5, 12BA6, etc. If this is not

convenient, the existing valves can be rewired in a series parallel circuit.

See here for

further details.

The next thing is to deal with the vibrator

and transformer. If possible, the transformer primary could be rewound

with twice as many turns using thinner wire. Under the assumption that

the vibrator is an Oak type, a 27R 5W resistor can be connected in series

with the drive coil. Simply installing a series resistor to power either

the transformer alone, or transformer and vibrator is not recommended.

The problem is that until the valves warm up, there will be no load on

the inverter, causing excessive voltage in the transformer secondary winding

which can cause insulation failure, damage to the timing capacitor and

arcing at the rectifier socket. Where the whole radio is fed from a resistor

this is less problematic as the valve heaters provide a constant portion

of the load.

However, there is a much more ingenious

way around the problem. It allows the original transformer to be used without

modification.

How to use a split reed vibrator to enable a 6V vibrator transformer

to operate on 12V. Note that the driving coil is not shown for simplicity.

Here, a split reed vibrator is connected

so it works as a DPDT reversing switch, applying +12V then -12V to the

full primary. In effect, the primary receives the same peak to peak voltage

that it did on 6V.

The centre tap is no longer used. The

advantage is of course the regulation and efficiency is as per original,

and the transformer needs no modification. The vibrator and its socket

do have to be replaced however, but as these items have the same appearance

as the originals, the radio will still look original. The Bland

shaver inverter uses this technique.

Of course, if the radio used a synchronous

vibrator for rectification in its original 6V form, then either a solid

state or valve rectifier will have to be fitted, but this is likely to

be preferable to replacing the transformer.

Dual Interrupter types.

These are commonly used in 240VAC inverters

or high power amplifiers, radio transceivers, etc. They are constructed

the same as synchronous types but with the contact timing adjusted so both

sets open and close at the same time. The contacts can be connected in

connected in parallel to increase current rating, or more effectively,

be used to switch two separate transformer primaries, or two separate transformers

with the secondaries in parallel. These latter two configurations

provide better current sharing between the contacts. In reality, it is

impossible to ensure both pairs of contacts open and close at exactly the

same time over the life of the vibrator, so the current rating is not actually

doubled as might be imagined. In the U.S., the term "Duplex" has been given

to this type of vibrator.

There are also types V7706 and V7712, but

data is not shown. As far has been ascertained without actually opening

one, these are the same as the V66xx types as far as connections and the

driver coils are concerned.

The dual-interrupter type became available

late 1948 / early 1949, and the first project in Radio & Hobbies to

use it was their "6-240 Amplifier", from February 1949. The article pointed

out that, previously, the highest power from a vibrator could only be obtained

from parallelling the primary and secondary contacts of a normal synchronous

type. The input power rating for this mode of operation was stated to be

30W at 6V. Of course, synchronous rectification was now not possible, requiring

a valve rectifier. With the new dual-interrupter type, the "6-240" amplifier

was able to draw a vibrator input power of 51W.

The circuit below, from Radio & Hobbies,

April 1951 (later revised for January 1957), illustrates the use of a dual-interrupter

vibrator. It is of a 240V AC 40W inverter, powered from either 6 or 12V.

The transformer is a Ferguson VT146 which is designed for 6 or 12V operation

by means of a tapped primary.

For 6V, the two primary windings are fed

independently from each set of vibrator contacts. This provides more even

current sharing. The 12V configuration simply has the two sets of contacts

in parallel, but as the current is halved at this voltage, the current

sharing is less critical.

This circuit from Radio & Hobbies, April 1951, illustrates how

a dual-interrupter vibrator is used. Contacts may be paralleled, or drive

separate primary windings.

Another AWA patent was for operation of 6V dual interrupter vibrators on either 6 or 12V without modification by using primary tappings on the transformer.

Ferris car radios and inverters.

With the standardisation of pin connections, these types actually have the same pin connections as the synchronous and dual interrupter types, except there's no extra set of contacts. This means that one often finds dual interrupter or synchronous vibrators plugged in instead, even though the extra contacts are not being used. It's a worthwhile modification to simply link the other socket pins to bring the extra contacts into being in parallel. While this has limited merit with synchronous types due to the later closure of the secondary contacts, it means that although current rating won't be greatly increased, the secondary contact will take over if something goes wrong with the primary contact. No doubt radio servicemen found it convenient that any MSP six pin vibrator could be plugged into these sets, without having to do any socket rewiring.

The reliability of Ferris car radios was partly due to their use

of the MSP Oak vibrator.

Astor car radios.

Type V4010 and V4016 are interesting

types. They also have a 6 pin base and are non synchronous. They are designed

as a replacement for the shunt driven Ferrocart

vibrators used in Astor car radios. Four pin Ferrocart vibrators actually

use a four pin Delco base. This is effectively a UX-6 base, with pins 2

and 5 physically omitted.

V4010 is 6 volt and replaces the Ferrocart

PM237, and V4016 replaces the 12 volt PM238. These vibrators are immediately

obvious because adjacent pairs of pins are strapped together on the underside.

The straps are so connected that the three active pins of the V4010/V4016

match up with those of the Ferrocart type. However, some versions have

the strapping internally.

Otherwise, they use the same components

as the normal series drive non-synchronous types, except that the drive

coil takes its feed from one of the power contacts. Also, the drive coil

is of higher resistance, since the applied voltage is twice the supply

voltage, due to the transformer action.

Unlike the shunt drive Ferrocarts which

the V4010 and V4016 replace, the Oak design retains their separate drive

contact, despite the use of shunt drive circuit. This means a considerably

greater life expectancy can be obtained before any adjustments are required.

Separate drive contacts used with the shunt drive circuit.

Depending on the source of data, the internal schematic shows the

V4010/V4016 as either a true shunt drive type, with no separate drive contact,

or as has been confirmed with all the examples in my collection, a separate

drive contact is used.

Types V4011 and V4017 are electrically the same, but without the strapped pairs of pins. It is not clear why the two variations exist, since they would appear to be completely equivalent, when plugged into a set designed for four pin Ferrocart vibrators. Indeed, I have never seen the V4011 or V4017. The likely answer appears that some of the "four pin" Ferrocart sockets were just that, and did not have holes for pins 2 and 5. Therefore a UX-6 base vibrator cannot be plugged in, short of removing pins 2 and 5. It appears V4011/V4017 are made without pins 2 and 5.

The three strapped pairs of pins immediately identifies the vibrator

as a V4010 or V4016. Note that some examples have the pins strapped internally.

Although I have not done tests, it would appear necessary to check the timing capacitor value when using an MSP to replace a Ferrocart in view of the PM237 and PM238 operating at 150c/s. On the lower frequency of 100c/s produced by the MSP, the timing capacitor may need to be increased.

Aged types.

Prefixed by "A", these are painted black

to enhance cool running. A typical type is AV5948. They are run for an

ageing period prior to final adjustment. Mostly, they appear in mobile

two way radio applications, such as the AWA Carphone.

Aged type shown in next photo below.

Reverse polarity types.

Suffixed by "R"; for example AV5948R.

These are synchronous types that have the secondary contact connections

swapped over, so that the output polarity is reversed from normal. An application

for this is where a radio might be transferred to a positive earth car

from one which was negative earth, or vice versa. Instead of swapping over

the transformer connections, a quicker alternative is to simply change

the vibrator to the other type. They are also used where split reed synchronous

power supplies are used in series. This is because the secondary centre

tap of one transformer has to be positive (the normal situation), while

that of the other has to be negative in order for the voltages to add.

On this note, the AV5948 is used with

the AV5948R in one of the AWA Carphone power supplies to provide 150V on

receive and 300V on transmit.

An "Aged" reverse polarity type, AV5948R. This is a 12V split-reed

synchronous type.

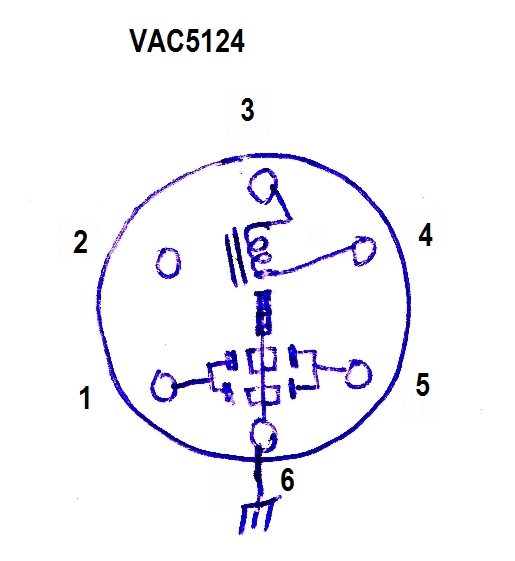

AC type VAC5124.

A rather obscure type, is one in which

6.3V AC is applied to the driving coil. The vibrator is thus synchronised

to the mains. So far, the only application I have seen such a type in is

a mains operated ignition coil tester. In this instance, the vibrator simulates

the points normally found in the ignition system.

Type VAC5124 has a 6V AC driving coil. Note the two separate coil

wires and the absence of the drive coil contact.

Despite the "5124" in the type number,

it has little in common with the synchronous V5124. Although the contact

assembly is constructed as though it were a synchronous or dual interrupter

type, this is not how it connects to the outside world.

The two sets of contacts on each side

are paralleled internally, and then brought out to pins 1 and 5. In this

regard, it functions as a dual interrupter type where the contacts are

paralleled. The result is a slightly higher current rating than if there

were only single contacts.

The most interesting aspect of this vibrator

is the coil design. Being AC, there is no need for the drive coil contact,

and this is omitted. In fact, such would be undesirable, since unless the

natural frequency of the vibrator is the same as the mains, or a harmonic

thereof, the vibration of the reed is not constant. It varies in a kind

of surging fashion, depending on the frequency difference.

Because of no drive coil contact, there

are two separate wires coming from the coil, which connect to pins 3 and

4. Also, unlike the standard types, the coil is a single winding of ordinary

enamelled copper wire. The shorted secondary wound in chromdioxide resistance

wire is not required.

One might surmise that this vibrator could be used on DC, if the coil was connected across the pull contacts, so it functioned as a shunt drive type. Indeed it can, although it was obviously never intended to be used this way. A series resistor should be included in series with the coil, in view of this being presented with 12V when the vibrator starts.

Radio Parts Catalog 1968-1969.

Oak Vibrators in England.

The English company, Wright & Weaire was another establishment outside the U.S. making Oak vibrators, under their "Wearite" brand. However, unlike the Australian MSP version, the Wright & Weaire version does not externally look like the original Oak, and the numbering system is totally different. Instead of V5123, for example, W&W will use NS/12. The can is of a wider diameter, and the base is crimped in place. The can is aluminium instead of zinc. Looking at the cut away diagram above, we can see that the can contains much more rubber for acoustic insulation. The entire can is lined, whereas the original design is not insulated against noise except for at the top and bottom. Presumably the thicker zinc stops most of the noise transmission by itself, whereas thin aluminium is not so effective. It is unfortunate that the crimped can construction has been used, but internally these vibrators should be as good as any Oak design.

Wright & Weaire vibrators type NS/12.

Oak Vibrators in the U.S.

Unlike the Australian version,Oak in the

U.S. changed the design of the can. The original zinc can with spring clip

gave way to wider diameter zinc and aluminium cans. One type of aluminium

can has a ribbed surface, presumably to aid heat dissipation. These latter

types are all of the crimped construction. Oak vibrators were also rebadged

under other names including Raytheon, General Electric, and Terado.

Examples of U.S. made Oak vibrators. At the far left is the

type on which the Australian AWA/MSP version is based. The finned can type

at right was also rebadged by Terado, and it seems, Raytheon and GE.

It says " OK 12 Volt". Some clown had decided to use a 6V vibrator on 12V because it appeared to work. I dreaded what I'd find inside, and indeed the mechanism and sponge rubber was coated in a black substance.

Don't run a vibrator with incorrect coil voltage, although it might

"seem OK".

Prior to taking the photo I had cleaned

it up, but the black deposit is still evident around the sponge rubber.

This kind of component abuse is always

appalling, in this case almost ruining a perfectly good vibrator. Thankfully,

the driving coil appears to have survived, although something seems to

have exuded from it particularly at the top of the bobbin. It would

appear that someone needed a 12V type but didn't have one, and discovered

that a 6V type would work instead. Yes it will, but with excess driving

coil current and the resultant overheating, the arcing at the driving coil

contact, and of course the excess reed swing giving an extra hammering

to the contacts. Who knows how long it would have taken to burn out the

driving coil. If only a 27R resistor had been connected in series with

it. It's rather reminiscent of people with vintage cars that feed 12V into

6V starter motors.

And yet, you can be sure whoever did this

would be the first to complain about vibrators being unreliable or some

such nonsense.

This V4016 shown below, refused to start. Upon opening it, the reed could be seen to be catching on the solenoid pole piece. The reed also was not centered at rest. In an attempt to correct this, it was found the reed was broken.

Reed catching on pole piece. It was found to be cracked.

This broken reed came from a fellow HRSA member. It was from a V4012. It should be pointed out these are the only two broken reeds I have seen in Oak vibrators.

Reed breakage is one fault that cannot be repaired, but fortunately

is a rare occurrence.

Another vibrator that wouldn't start - a V5105. Someone in the past had replaced the foam rubber. Unfortunately, they had used a type of foam that disintegrates into a sticky corrosive mess. After a good clean up, this vibrator worked perfectly. The connecting wires to the base had also been replaced with ordinary rubber insulated type. This had gone brittle. The best kind of wire for this is ultra flexible instrument lead wire.

Don't use this kind of foam to replace the acoustic insulation!

Zinc can creeps under pressure from spring clip.

Slot is cut to allow zinc to return to original shape. Can edge

is rolled on hard surface to bring the shape back to original.

Base Repair.

The foam rubber which supports the mechanism

on the base can either be in perfect condition, or it can have totally

disinitegrated. Sometimes the rubber has hardened to the point of crumbling

apart and can be heard rattling around inside the can. There is also a

rubber cap in the top of the can, in which the top of the mechanism rests.

The foam rubber can be replaced with modern "Aerotape".

Base foam deteriorated on left, and rebuilt with Aerotape on the

the right.

Three discs of Aerotape are cut to the

diameter of the base. Two are stuck down to the base, and then the mechanism

is attached by resoldering the wires. Use a jeweller's screwdriver to poke

holes in the foam for the wires.

The third disc has a U shaped slot cut

in the centre so it goes around the bottom of the mechanism.

Usually, the rubber cap at the top of

the mechanism lasts better than the base, but if it needs replacing, the

same Aerotape can be used there too. However, the thickness is such that

if used for the top portion of the cap, the mechanism will have pressure

against it and will not be able to "float" freely. This is undesirable

because it alters the vibrator operation. Instead, a thin piece of felt

does the job, and Aerotape is used just for the side piece. Ensure that

when reassembling, that the mechanism can indeed float freely.

(The vibrator shown in the above photo

is from this

Breville radio).

The first identifying feature is the two dimples in the snap ring.

The labelling is very simple.

Rest of the labelling.

Opened up, we see the rubber stack support and top rubber are disintegrating.

The contacts look good.

Stack support rubber definitely has to be replaced!

Base removed.

Base cleaned up. Fabric disc removed as it will serve no purpose

with the new rubber.

Two discs made from self adhesive "Aerotape" are attached to the

base.

Holes for wires poked through using a jeweller's screwdriver.

Vibrator mechanism reconnected to base.

A third disc of Aerotape is attached. It's cut into a U shape to

fit around the tags, and a smaller piece fits around the drive coil wire.

For the top of the can, a piece of felt is cut out to take place

of the top part of the top rubber.

Felt disc is inserted, and strip of aerotape (same height as top

rubber) is attached to top to hold felt in.

Vibrator worked well after contact cleaning and minor adjustment.

Ready to go back in the can, this photo shows how the split washer

fits between the base and where the dimple is around the base of the can.

Do not install mechanism like this, but fit the washer to the can

first. Then as the mechanism is inserted, work the rubber through the washer.

As can be seen, only someone very familiar

with the Australian and U.S. versions would notice one from the other.

Apart from the label and snap ring, the most identifying feature would

be the blue tape around the drive coil. AWA did have some minor variations

with the stack, so it would be otherwise difficult to tell from this alone.

I am not certain, but it did appear that the contact arms of the U.S. version

are softer, in that it seemed easier to adjust them. This in itself does

not seem to be a deficiency, because the amount of the adjustment this

vibrator required was no more than a typical Australian version.

Incidentally, the V5124 is one of the

few which existed in the U.S. and Australia with the same type number.

| Volts | Coil Resistance | Inductance | Q | Examples of types |

| 4 | 8.5R | 640uH | 0.162 | V6804 |

| 6 | 12R | 1.1mH | 0.17 | V5105, V5124, V6606, V7706, V5211, V4006 |

| 12 | 35R | 1.1mH | 0.09 | V5123, V5258, V6612, V7712, V5958, V4012 |

| 6 (shunt circuit) | 24R | 1.2mH | 0.11 | V4010 |

| 12 (shunt circuit) | 73R | 1.5mH | 0.06 | V4016 |

| 24 | 131R | 4.06mH | .08 | V6724, V6824, V6624, V6524 |

| 32 | 230R | 3.64mH | .054 | V6632, V6532, V6732, V6832 |

The number of pins further narrows down the types. For example, 4 pins means a non-synchronous type such as V5105 or V5123. Six pins means synchronous, dual interruptor, or Ferris type non-synchronous. The Ferris types V4006 and V4012 can be identified in that pins 2 and 4 show no connection whether the vibrator is operating or not. Six pins could also mean it's a Ferrocart replacement V4010 or V4016, and checking for continuity between adjacent pairs of pins will confirm this.

Type VAC5124 can be identified by a resistance of 16 ohms between pins 3 and 4.

To differentiate between synchronous and

dual interruptor types, the timing of each set of contacts has be examined

on a CRO by using a set up like this.

Seven pin types are split reed synchronous,

and once the voltage rating has been determined, the type can be further

narrowed down. However, this does not determine if it is an "R" (reversed)

suffix device. To do this requires the primary and secondary contact timing

to be examined on a CRO, or simply by using the vibrator in a known device

and seeing if the output voltage is reversed. Note that reversed types

are in the minority and not generally encountered with domestic radio equipment.

Ferrocart replacement types V4010 and V4016, are immediately identifiable by their three pairs of strapped pins.

Of course, if one wishes to open the vibrator for examination, it can be narrowed down to a few types. However, it is a shame to break the stamped soldered seal on a prisitine N.O.S. type just to do this.

Old Type Numbers.

Initially, Oak vibrators were supplied

using a different numbering system with two digits and two letters. This

was later dropped, and the Vxxxx system was used exclusively.

| Old Type | Later Type |

| 17XH | V5105 |

| 18XH | V5123 |

| 185XH | V6524 |

| 33ZH | V5278 |

| 35ZH | V5124 |

| 36ZH | V5258 |

| 365ZH | V6724 |

| 63UH | V6804 |

| 35UH | V5211 |

| 66UH | V5948 |

A hundred bucks for a vibrator?

This interesting eBay ad prompted the question

of what is a vibrator worth. Well, certainly not $100! The seller obviously

visited this site, because the ad title is partly cut and pasted from this

page's heading.

About a week later up came another ad:

Another seller jumps on the $99 vibrator bandwagon.

Obviously, the second seller saw the first

ad and decided that's what vibrators are worth. Clearly, both sellers are

not familiar with radio vibrators.

Generally for typical radio vibrators,

I don't pay more than about $5 each. In the past I would sometimes pay

$10 for a new in box Oak, but have enough now not to need to pay that much.

When I occasionally buy a bulk lot of

vibrators from the U.S., they work out to no more than about $5 each. As

an example, I recently bought a lot of nine vibrators from the U.S. for

US$5.00. That works out to about one Aussie dollar per vibrator!

This

lot of 19 vibrators cost only $14.00. True, the postage puts the cost

up, but still usually works out favourably when buying a bulk lot.