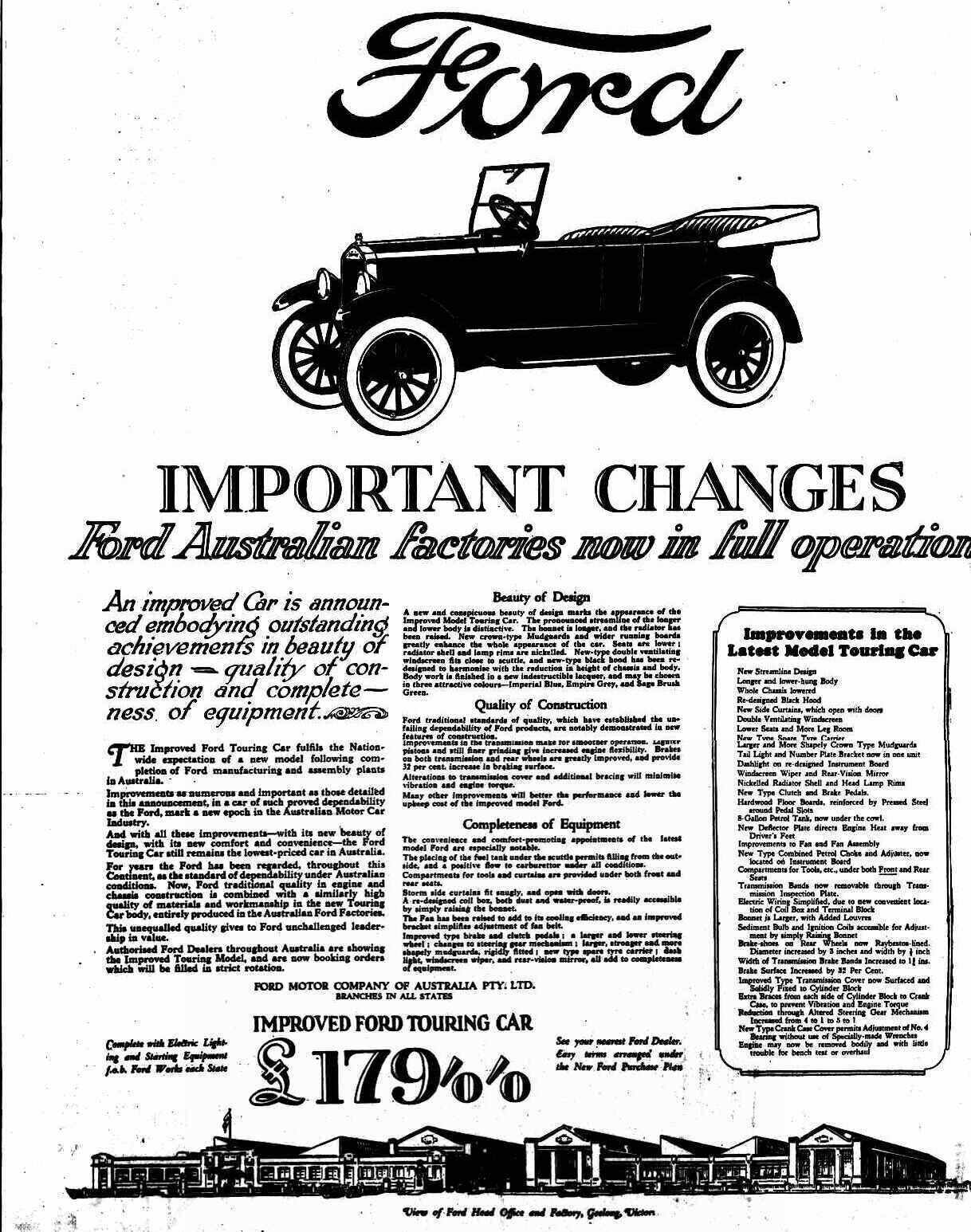

This ad in the July 2002 "Unique Cars" led to a new hobby and many interesting adventures.

This ad in the July 2002 "Unique Cars" led to a new hobby and many

interesting adventures.

Up to this point I have compiled several articles relevant to the Model T Ford, and described some of the accessories that I have made for and used with my own car. Here at last is the article about the car itself.

My Introduction to the Model T Ford.

During 1987 at the age of 19, I was browsing

some of the automotive books in the then excellent Willoughby Library.

Unlike most other libraries, this one had a good collection of technical

books, many of them quite old too - which only helped my interest in vintage

technology. One of the books was about restoring the Model T Ford, authored

by Floyd Clymer. It was, I think, written in the late 1960's.

Apart from being aesthetically a very

good looking car, I immediately related to the design of it. Obviously,

this was a car made to be serviced, and it wasn't full of unnecessary parts.

Aside from that, what really stood out

was the parts availability. Apparently, some parts were still available

from Ford in 1968.

So, I made up my mind that the Model T

Ford would be the car for me. Still a student with no income, there was

no way I'd be able to buy one, but it remained a dream.

All I could do is look at ads in the "Trading

Post" and confirm that cars and parts were not difficult to get. There

was even an ad in one of the daily rags around the time, from Alto Ford

in Artarmon, for a brass Model T which was fully registered. I vaguely

recall it was only $7000, which confirmed that Model T's were also not

expensive.

And that was it for the time being. Once

I started work in 1990, my immediate priority was to buy a house, so the

Model T remained well off into the future.

Getting Closer

It was in the late 1990's when the Easter

Show had moved to Olympic Park, and whilst wandering around I spotted a

Model T all on its own, near the stadium. It was a black one imported from

the U.S. since it was left hand drive. I now know it would have been a

late teens/early 20's model. No one was around for me to ask questions

about it, so I had a good look around, and the more I saw of it, the more

I liked it.

Again, now with a mortgage in the way,

and with no garage at my house, I didn't seriously think about buying one

just yet. It just reinforced that it was the car I wanted.

Around 2001, I started browsing the internet

for Model T stuff, and information poured forth, including a very interesting

forum hosted by the Model T Ford Club of America. Reading the various postings

further increased my knowledge of this car. I learned that there were changes

to the cars over the years, and that the last of them, the 1926-27 models

were the best from the point of view of mechanical improvements. For example,

they had proper rear brakes, a wider transmission brake drum, a more rigid

power plant assembly, and so on.

So, this would be to model to look for.

The newly built Geelong factory, and the announcement of the Improved

Ford.

Not long after this, I happened to stop in at All Fords Day, at Peter Warren at Warwick Farm with a friend, and noticed the Model T's on display. Again I had a close look at them, but no one was around to talk to about them. Sometime later, coming back from Bathurst one afternoon we spotted a convoy of Model T's cruising at quite a good speed along the highway. It seemed the cars could keep up with normal traffic.

July 2002.

In June 2002, I was browsing "Unique Cars"

in the Penrith Coles one evening and saw an ad for an original 1926 Model

T. What I particularly liked was that it was original - I didn't want someone

else's modified/butchered restoration or something with missing parts.

It stuck in my mind, but again I had the mortgage, etc. However, when the

July issue came out the ad was there again. My friend who knew I really

wanted it spurred on my enthusiasm, so I decided I'd at least ring the

owner to ask about it. I was on the phone for about an hour and a half

talking about it. I just had to go and see it. That weekend we went up

to Port Macquarie where it was to have a look. Yes, it was a real unmolested

1926 Model T Ford. Apparently, it was up for sale because the owner's wife

wanted a swimming pool, and the money had to come from somewhere. He was

not pleased about this. I had a good look over it and as far as I could

tell it was all there, and wouldn't take much to get it going.

I certainly felt very connected with this

car and it was time to make a decision. I could keep it in my friend's

garage just up the road, so storing it would be taken care of. Next, how

to afford it. The asking price was $11,000. At the time all I could offer

was $9,500. That's all I had in my savings account. I rang the owner and

said that's all I had. It would be now or never that I ended up with this

car. He wanted it to go to someone who would look after it, not to someone

who wanted to cut it up for a hot rod. Apparently, there had been interest

from other potential buyers who wanted to do just this. He could see by

the way I looked over the car that I wanted to keep it original, and my

offer was accepted.

That weekend, we went and got it, bringing

it back to the Blue Mountains. From now on, my life was to change with

this acquisition....

History of the car.

The seller had told me the car originally

belonged to a guy from Shepparton. It found its way to Billabong Motors

in Lockhart which is where he first came across it - he was part owner

of the business with his brother. His idea was to restore the Model T and

have it as a window display at the dealership. He had a falling out with

his brother and moved to Port Macquarie, which is where I picked the car

up from. I was told there were still all the spare parts - complete power

plant, guards, etc., still at Lockhart and they were included in the price

of the car.

Upon arranging to go and get them, I discovered

that they had all been scrapped, and had the Model T still have been there,

it would have been too. Such was the animosity between the brothers.

I was thankful just to have got the Model T.

The car was, according to the decal on

the windscreen, last registered in 1954 in Victoria. The original number

plates were still on the car.

Billabong Motors in Lockhart.

Some years later, at the Echuca 2008 rally, I was approached by some people that knew the car. One lived near Port Macquarie and had seen the car for sale, but more interestingly was the story from someone else that it had been traded in on an early Falcon. The T had been moved to a shed in nearby Wagga, and around 1975 had been put up for sale without any buyers. Then it was moved back to Billabong motors.

The Learning Curve Begins.

I noticed the car had "Made in Canada"

on the radiator cowl and cylinder head. So, it seemed all the Australian

T's came from Canada. I soon learned they were actually assembled in Geelong

from 1926 onwards, with Canadian parts. Hence the term I'd seen in advertisements,

"Geelong Tourer" to describe the 1926-27 Model T's.

It turned out that we got Canadian T's

in Australia because 1) right hand drive cars were used in some parts of

Canada and were therefore being manufactured there, and 2), Canada is also

a Commonwealth country, so tariffs were less than they would be if the

cars were obtained from the U.S.

I had been working on cars since before

I got my licence, but the Model T was very different, so now had to learn

the Ford way of doing things. The MTFCA forum was particularly helpful,

as was advice from Harry Black, the then owner of "Henry's Model T and

A Parts" in Melbourne. He imported Model T parts from the U.S. My assumption

that Model T parts were easy to get was right; I discovered a multitude

of suppliers of reproduction parts. And they were quite inexpensive when

compared with a modern car!

The first thing to do was have a closer

look at what needed to be done to get the car drivable. The tyres were

not surprisingly hard and cracked. I noticed that the band linings were

partly rotted and coming off the bands, so those two things would have

to be dealt with first before I even thought about driving it.

All original. It turned out to be a low mileage car with not a lot

of wear.

Although I looked into it, I had no desire to respray the body or redo the upholstery. I had assumed it would be required for registration, but I found out otherwise - the car just had to be mechanically good and it didn't matter what it looked like. Doing body work has to be the most boring job on a car. I'd rather get in and drive it than spend hours trying to make it look pretty. It was a huge relief to find this out because it meant the car would be registered sooner than expected.

The coil box lid was missing.

The last registration decal is visible on the original windscreen.

Relining the Bands.

There was a delay in getting the band

linings, so not much happened for about a month. I did inspect inside the

engine pan to see there was nothing obviously loose or broken. Coming from

the Riverina district, there was a very hard red earth stuck to the underside

of the car, so I spent some time scraping this off.

Changing the band linings was the first

thing I did. I knew that with the 26, or as I learned it was called, the

"Improved Car", one could change the bands without taking the hogshead

off, but for now I thought it wise to have a look inside and see that the

all important oil funnel was clear. And so I learned the joys of removing,

and replacing the Model T hogshead (transmission cover). It's particularly

awkward in the Improved Car because part of the firewall is in the way.

However, in my car this had been conveniently cut and bent out of the way.

Later, I learned that other 26's had this done to them for the same reason.

To get the hogshead off entailed removing the starter motor first. When

I did this, the magneto winding was seen to be damaged in the vicinity.

This is a common problem when someone attempts to remove the starter, without

removing the Bendix first.

Hogshead off ready for the bands to be re-lined.

Bands fitted with new linings. This was straightforward using the

instructions provided with the Mark Auto linings I used.

Newly lined bands back in the transmission.

Lining the bands was easy. There was some

debate on the forum as to what should be used. My thoughts were to use

what Ford used; i.e., cotton. After nearly 16 million Model T's, one could

say that Ford knew what was best. Many people seemed to like Kevlar, but

as that's harder than the steel drums, the drums would wear instead of

the lining. It seemed that Kevlar suited those whose driving technique

was such that cotton bands had a short life.

With the bands back in, and the hogshead

back on, I could attempt starting the car.

First Start.

The car had been supported on stands so

the wheels could rotate freely, and I could test the transmission. A new

6 volt battery was ordered through Beaurepaires in Penrith. This was the

first 6 volt car I'd owned or worked on so was curious to see how quickly

the starter rotated. I had noted on the forum how many owners used a 12V

battery instead, but as an electronics engineer, I detest the abuse of

electrical parts this way.

At this point I had not done any work

on the ignition system, except to see that each coil buzzed as the crank

was rotated. All the coils were original, except for one. The timer was

an original roller type. The wiring was all original, but good enough for

testing.

Anyway, a few litres of petrol were poured

into the tank and attempts made to start it. Unfortunately, nothing much

happened and I flattened the battery before it was even getting close to

starting. The battery was recharged, and another attempt made the following

weekend. Again it wouldn't start. Another week later, I replaced the float

valve in the carburettor using the then recommended "Grose Jet".

This time it did start, and it seemed

to run smoothly. Of course, in retrospect, I should have made sure all

the valves were closing properly first. The transmission pedals and hand

brake did what the "Ford Instruction Manual" said they would, so the transmission

was probably OK too.

Exhaust Replacement.

On a visit to Melbourne, I picked up a

new exhaust pipe and muffler from Harry Black, along with miscellaneous

other parts. The exhaust pipes were being made locally, as they are different

to the U.S. ones. This is because of the pedals getting in the way on right

hand drive cars, and the pipe requires a different bend to clear them.

The thread on the exhaust manifold was non existent, so I wrapped a strip

of copper sheet around the join and secured it with hose clamps. This bodgie

repair actually lasted a few years before I installed a new manifold. The

original muffler was almost rusted through as well, so was also replaced.

Joining the Club.

My intention was to have the car on full

registration, so I checked with the RTA before I bought it, to confirm

I could do that with such an old car.

I did not relate to the concept of historical

registration with all the restrictions that entails. I am a firm believer

in using vintage technology as a normal thing. Funnily enough, the guy

I bought the car from remarked "how cool it would look going to pick up

a pizza in it". My reply was, "that's exactly what I'm going to do with

it".

I didn't particularly want to get involved

with a club because of the original body work of the car. I had assumed

they wouldn't like such a car in a club. However, at a swap meet I noticed

a guy selling some Model T parts. He was a member of the Sydney club and

assured me that "any old rusty piece of tin will do" when I described my

car. Then, I emailed the club about the oil I should use for the engine

and diff. I got a call from the club president, which was quite enlightening,

and so went along to the meeting. They all seemed to like my car when I

described it and showed a photo. Surprisingly, I was told that a complete

car like mine was actually quite rare - something I was not aware of. I

was so glad I had not resprayed over the original paint. As one person

remarked to me; "You can restore a car, but you can never unrestore it".

The car came to be very much liked by some of the club members, although

I did acquire a reputation for insisting on the original design. Many arguments

were had about the use of 12V batteries and distributors - all of which

fell on deaf ears. But, you've got to just switch off and let people do

what they want to do - it is their car, after all.

However, I did note the more modified

cars were, the more problems they had. As I said before, after nearly 16

million cars, it's safe to say Ford knows best.

Amusingly, there was the wife of one member

who thought my car was a disgrace to the club, when it appeared on the

front cover of the magazine. Another wife remarked to me rather sarcastically,

at a club meeting, "We love our cars", as if to say I didn't love

mine because of the worn original paint work and upholstery.

The rest is all history now of course,

and I've participated in many of the club runs over the years. It is a

most enjoyable experience to drive with a convoy of Model T's, and we have

been to many interesting places that I wouldn't have otherwise been to.

Being on full registration means I also drive the car normally outside

of club events. For example, I always drive it to the HRSA meetings at

Winston Hills.

Tyre Replacement.

Back to the car now; five new tyres had

been bought through one of the club members. I don't know we managed it,

but my friend and I had all of them replaced in a day. Clincher tyres are

a pain to replace, and this is made even more difficult by having tyre

flaps as well. The old tyres were so hard they had to be cut off with a

hacksaw.

First Drive.

Anyway, it was now ready for a test drive.

Alas, it barely got up the driveway, but I managed to drive it to the end

of the street and back in low gear. I was of course unfamiliar with driving

a Model T, so dared not try it in high gear at this point. There was very

little power anyway.

First drive, October long weekend 2002. It had very little power

and I ordered the parts to rebuild the ignition the following day.

There were continued problems with fuel leaking from the carburettor. It seemed there was still dirt and rust coming down from the petrol tank, which was preventing the float valve closing. It was really quite frustrating and irritating, and I sometimes wondered what I had got myself into with this car. Installing a paper fuel filter finally fixed that problem.

The paper fuel filter remained for several years until all the rust

and dirt had finished coming down from the petrol tank. My bodgie exhaust

connection can be seen with the copper sheet and hose clamps. A new exhaust

manifold was fitted later to enable the proper nut to secure the exhaust

pipe.

The only accessory which had been fitted to my car was a Carbur-Aid. It is installed between the carburettor and intake manifold, and is supposed to be an fuel economiser device. When the manifold vacuum is sufficiently strong, the steel ball rises, admitting extra air, and leaning the mixture.

An advertisement from 1925 for the Carbur-Aid. At right is the Carbur-Aid

itself.

It's something of a novelty, and I doubt it really works. Fuel consumption with the Carbur-Aid is 20mpg, which is no better than the Ford specification.

Ignition Rebuild.

It was obvious now that it was also time

to rebuild the ignition system. The coils were fitted with new points and

condensers, and the timer was replaced with a new Anderson. I had no proper

means of testing coils back then, so simply adjusted them for 1.3A at 6V.

A few short test drives over the next few weeks confirmed all was good

here now.

Shortly after, I replaced all the wiring

with a new reproduction harness.

The fuel tap still leaked which required

draining the tank after each drive. This was annoying me and so I finally

replaced it with a new John Deere AM3100T. The concept of a brass plug

type fuel tap was never going to be reliable, and attempts at using valve

grinding paste weren't completely successful. This was one instance where

the modern part is superior.

New glass sediment bowl eliminated the problems with the original

fuel tap. An outside oil lime was also added after conrod babbit failure.

Now with the car drivable, it was time to do the things necessary for registration. The king pin and tie rod end bushings were replaced, and also the steering shaft bushing. A local glass company was able to cut some new laminated glass for the windscreen. The original was plate glass and obviously lethal in an accident. Unfortunately, the new glass meant no more 1954 registration decal. However, I did keep the original pieces of glass. (In the present time I could actually photograph the original label and print it on an adhesive clear label)

Faulty Magneto.

Trying the ignition on magneto didn't

work particularly well, with something like only 9V at high revs. I drove

it to the end of the street on magneto, but when the engine revs dropped,

it stalled. I never ran it on magneto again. I did try an in car recharge,

but it made no difference. The MTFCA forum led one to think that the car

would not run properly at speed without a magneto, unless a 12V battery

was used instead of 6V. There was no way a 12V battery would go near my

Model T, so that wasn't going to happen. Funny thing was, it seemed to

drive just fine on 6V, and when I mentioned that to one of the very knowledgeable

people in the club, he sad "yes, you can do that". So, I stopped worrying

about it. To save repeating a whole lot of stuff, I go into some detail

on the subject here.

A year later while doing an oil change,

I discovered the reason for the faulty magneto. A screwdriver blade was

noticed lying in the bottom of the transmission. It had obviously been

dropped in. It also explained the soldered up dent in the side of the transmission

housing.

More Lights.

Indicators were installed next. I made

up an electronic

flasher. Originally, I used generic hot rod indicator lights at the

back, but a few years later replaced them with Model A rear lights, which

look far more period correct. With the dual colour lenses, I could also

have additional brake and tail lights. The front indicator lights were

some kind of motorbike light I got at a swap meet. I mounted them on the

radiator cowl bolts. Contrary to what a lot of club members think, there

has been no problem obtaining 6V bulbs and other parts.

A brake light switch was also installed.

I used a micro switch which has its lever bearing against the brake pedal.

As there was only a single rear red light, it was necessary to combine

this with the brake light. Normally, this is done with a twin filament

bulb; the lower wattage filament being the tail light, and the higher wattage

for the brake. Because I didn't want to modify the original single contact

arrangement, I devised a method to use the one bulb for both functions.

Here, the 18W bulb runs through a 0.47 ohm 10W resistor from the lighting

circuit, so it appears as though it's a lower wattage. When the brake switch

is actuated, the resistor is bypassed with the full 6V being fed to the

bulb, and it lights at normal brightness. Thus, the distinction between

the brake and tail light is quite obvious. Later, when I had installed

the Model A lights, I simply wired the red portions in parallel to the

existing tail light. Now there are three red lights at the back which is

far better from a safety point of view.

While it was not legally necessary to

install the brake light and indicators, since the car was not made with

them, I felt it wise given that modern drivers do not know hand signals.

Registration.

One of the last things was to degrease

the rear brakes. This is when I started to learn how difficult getting

the back wheels off was without a puller.

Finally, the missing seat upholstery was

replaced by a piece of carpet found in a skip outside a carpet shop in

Penrith.

The registration inspection was a farce.

First thing was to get the car weighed at Box Hill, as I was told the weight

would need to be known to get the Blue Slip. Then, off to the service station

at Freemans Reach for the inspection. After waiting quite some time, the

guy there looked over the Model T and then we did the brake test. He just

wouldn't accept that with two wheel brakes it would not give results like

a modern car. Interestingly, the electronic brake tester blanked out when

the engine was running because of the magneto. So we had this silly situation

of letting the car roll down a hill with the engine off. It actually passed

the hand brake test quite easily, but the foot brake never quite made it.

After several attempts he gave up and

passed it anyway. But, the real problem was to come next. This guy was

a stickler for what the book said...and was unsure about the chassis number.

Model T's in Australia did not have chassis numbers. The convention is

therefore to use the engine number as a chassis number. Under the advice

from the club, I had riveted an aluminium plate onto the chassis with the

number. Apparently, it was meant to be stamped directly into the chassis,

and the aluminium plate stamping was only for club registration.

This caused a stuff up, but he passed

the car on the basis that it was mechanically OK, and left it up to the

RTA to decide if the number placement was acceptable.

We got to the registry in Penrith, and

the lady was just about to hand over the plates when she said words to

the effect of "I just better check".

Alas, registration then and there was

declined. Instead, I had to take the car on another day to the RTA inspection

place a few blocks away.

Plates at last.

I was nowhere near confident of driving

the car out on the open road yet, so for the trip to Penrith I got one

of the guys in the club to drive it for me. It was a rainy day, and with

no hood left, I had a blue tarp secured to the hood bows. The flapping

sound was unbelievable as we cruised down the highway. Arriving at the

inspection place, I was worried about what they'd say when they saw the

non existent upholstery and the tarp for a roof. Luckily, my fears were

unfounded, because the guy there loved it, and said "don't change a thing".

He passed it on the proviso I stamp the numbers directly into the chassis,

which I did. Back to the Penrith registry, and at last I had the number

plates. The trip back up the mountains was uneventful, and my acquaintance

was surprised how well it went with the original engine.

From here on, it was now a matter of longer

and longer trips as I became used to driving. I would say it was probably

about three months before driving became second nature.

Given that at the time it seemed to rain

most weekends, I decided to get a new hood made up. The remnants of the

one on the car weren't original anyway, but they're stored in a box just

for the sake of keeping the car's history. An upholsterer at Faulconbridge

did the job for me, his first of this kind, and I was very pleased with

the results.

Once I was regularly driving the car, I installed a bike speedo, mainly to keep track of the distance I'd driven. When the T's were built, a speedo was only an accessory. I had learned that the magneto interfered with certain types of bike speedo, but discovered that the Sigma Sport type worked OK in the Model T. It is also important to note that it's easy to break the speed limit with a well running T in a 60km/h zone, so this is another reason for the speedo.

Another installation was a 6

to 12V converter. This was primarily to run a 12V tyre compressor,

but I also used it with a car fridge.

It almost goes without saying that I had

to install a valve radio. The story of that is here.

Things that went wrong.

Considering that everything was original,

reliability wasn't too bad, but there were several memorable incidents

over the years.

The first surprise was the failure of

the No. 2 conrod babbit. A loud knocking appeared ascending Lapstone Hill

after my first club run to Belgenny Farm in June 2003. My acquaintance

in the club taught me how to fit another conrod, and while at it, I ground

all the valves. After this, I installed the accessory outside oiler and

never had the problem again.

The next incident was a fan blade breaking

off at Valley Heights on my way home from Motorfest in January 2004. This

was no big deal as I could disconnect the fan and keep driving.

A tour around Parkes was done during Easter

2004, and considering the distance, nothing at all went wrong. So much

for Model T's not being able to run their ignition properly on 6V; the

car flew along the highway at a great rate of knots.

While previously investigating poor magneto

performance, I had noticed crankshaft end play. Slightly concerned this

might be a bad thing, I fitted a shim to the 3rd bearing. This opened a

can of worms because then I discovered all three bearings needed to be

taken up. The clearance, especially of the 3rd bearing was surprisingly

large, yet the engine never knocked. A considerable amount had to be filed

off the cap, as well as all the shims removed. The centre bearing needed

all the shims removed, and the first bearing needed one removed.

Not having any means to get the power

plant out of the car, I actually took up all the bearings in the car. It

was a difficult job, but I did it. The engine was rather difficult to crank

at first, but after a hundred km or so it was loosening up again.

In October 2004, the diff failed on a club

run. The pinion gear broke a tooth as I drove into West Ryde. This shouldn't

have been a surprise, as I'd been driving all this time with no thrust

washers - these are originally babbit and break down. The rear end was

rebuilt by one of the club experts - it was easier to tow the car to his

place instead of mine.

All was well again, but then soon after,

spark plug fouling began and in April 2005, I replaced the piston rings.

A club run in May of 2005 resulted in

an incident on the M4 at Duck Creek. One of the valves had broken and punched

through the cylinder head. Another tow home, and I replaced all the valves

with new one piece types.

Note the hole in the No.4 combustion chamber.

The Dingo Farm run in November 2005 was

another memorable occasion, with a very poor running car. It started running

very rich, and to compound memories of this run, one of the headlight brackets

cracked. My poor welding skills weren't good enough, because a few months

later, the headlight broke off altogether, rolling across the M4 at Penrith.

Luckily, it didn't get squashed by another car.

By this time also, both of the back wheels

had needed to be rebuilt because of loose spokes. As I got the car, wedges

had been hammered in between the spokes, but this wasn't the right way

to fix the problem. Instead, shims needed to be put between the spokes

and the felloe.

The fuel problem was not improving and

the plugs were fouling again. The car just didn't run like it used to with

poor top speed of only about 65km/h and that was pushing it. This was eventually

fixed by replacing the needle and seat, and replacing the Grose Jet with

an ordinary float valve needle and seat, except the needle was neoprene

tipped. And, with new Champion X plugs fitted, we were back into

the 70's (km/h). It turned out that the quality of spark plug had a lot

to do with 6V operation as well. The original Lodge plugs were excellent,

but when the oil fouling had started, I had replaced them at first with

Motorcraft F11's which worked well until they too fouled, and then experimented

with modern 14mm plugs using adaptors. The latter performed extremely poorly

with overheating and poor top speed.

A trip to All Fords Day in 2006 was remembered by a broken valve pin. I had to drive from Ropes Creek to Liverpool on two cylinders! Once at AFD, I was able to insert a thick split pin as a temporary measure, which did the trick. A month later, another one broke, and this time I knew what it was straight away. It turned out the repro pins I installed when replacing the valves were of soft metal. I put all the original ones back. Later, I used ground down 7/64" drill bit shanks which have been faultless.

By 2008, it seemed the new piston rings had already worn. Compression was low. In the course of replacing the rings, and checking bearing clearances, I managed to crack a piston. This meant I had to replace all the pistons, as well as the rings, because cast iron pistons are no longer made, and I didn't have any spares. So, a new set of aluminium pistons went in. The lighter cast iron pistons of the Improved Car didn't feel much heavier than the new aluminium ones, contrary to what I had been told. I certainly couldn't tell the difference in the way the car drove once the aluminium pistons were fitted.

Purple Head.

The piston replacement was just before

the Echuca Rally in September 2008. Apart from one incident, that trip

actually went very well.

I was on the final part of the journey

from the Blue Mountains to Echuca, about the cross the border near Nathalia,

when I smelled something burning. When I opened the bonnet, I was greeted

with the cylinder head glowing purple and smoke coming off it. No water.

Air cooling doesn't work particularly well with a Model T engine!

Waiting for the engine to cool before adding water.

The brown stain of rusty water had been a feature of my car for

quite a while.

Since I had the T first drivable, it had

gradually developed a boiling problem which was getting worse and worse.

At its worst, the car would use about eight litres on any trip. I have

always used the "poor man's motormeter" to check the boiling. That is,

the water bubbling from the radiator cap would tell me how hot the engine

ran. Except, this time it didn't. I had simply assumed that as it wasn't

bubbling, it was running cool enough. Well, trouble is, if there's no water,

there's nothing to bubble!

I gave the engine 20 mins to cool down

and then ever so slowly poured water into it over about a 10 minute period,

so as not to crack anything.

I got away with it, because all was well

when I restarted, and no further incidents like this happened. The car

ran very well throughout the rally, and even one of the American visitors

remarked at how well it drove when I allowed him to drive it back from

Bendigo to Echuca.

Broken Crankshaft.

In October 2009 came the big one. I had

expected it, and had planned for it by taking out roadside insurance a

few years previously. It is a fact that anyone with a Model T running its

original crankshaft will have it break, especially if the car is regularly

driven. I had already gathered a small collection of Model T crankshafts

in anticipation - they were easy to come by then, because many members

in the club had their engines modified to take Model A crankshafts.

On the way to a club run, as I was driving

through Warrimoo, I heard a sound which reminded me of a delaminating fan

belt. I thought I'd deal with that at the next stop, Glenbrook, which was

only ten minutes away. Alas, a buzzing sound then developed, and I could

feel a strange pulsing coming through the pedals.

I pulled over, and once I opened the bonnet

it was obvious. The crankshaft pulley was pointing upwards slightly. When

I took the spark plugs out, I could see the pistons in positions they wouldn't

normally be in. Not surprisingly, I couldn't crank the engine - it was

totally stuck.

I calmly rang up the NRMA who came and

put the T on a flat bed and took it back home.

With the cover off the pan, it was as

expected; a break in the crankshaft. It was between No.1 and 2 conrods.

There was a loose piece of cylindrical metal lying in the pan cover. This

was part of the camshaft which also broken as a result of No.1 conrod hitting

it.

Note the missing piece of camshaft. The oil tube had been slightly

bent as well.

Like growth rings on a tree, it seemed the crankshaft had been cracked

for quite some time before it finally broke.

For the first time in its life, the engine

had to be removed from the car. Once the engine was out and in pieces,

it was clear I'd have to get it rebabbited. The front bearing had been

damaged. If it wasn't for this, I would have attempted fitting one of my

spare crankshafts.

Off to the well known engine builder Bob

Croft for this work. He remade all the bearings and was able to return

my original No.1 conrod to the engine. He checked my replacement crankshaft

(a 1927 EE type) for cracks, and fitted it. I had the option of having

the cylinders rebored. The existing cylinder wear was about .006"

which was pretty good. I had long known this was a low mileage car, so

wasn't surprised. However, I figured Bob won't be doing this work forever,

so if I got it rebored now I'd never have to get it done later. A trade-off

was I'd have to have new pistons - only a year after I'd replaced them!

I gave my "new" old pistons to a friend who was building a car.

Broken crankshaft and camshaft.

Once I had my block back, it was a matter

of fitting the camshaft and valves, and then reassembling the power plant.

The transmission drums were in pristine condition so didn't touch the transmission.

After a long thought about it, I decided to remove the magneto. I didn't

want to rewind it, and I didn't know anyone else who did that. Besides,

there was still the possibility of a magnet flying off, and I'd driven

all these years on 6V without any problems. Having decided that, oil paddles

were installed instead.

After a couple of days work in early January

2010, it was ready to take out into for a test drive. I was pleased to

see it was all perfect. In view of all this work, I finally decided to

replace the radiator. The boiling was not going away after repeated attempts

at cleaning out the radiator, and I didn't want to ruin my newly rebuilt

engine. A new Bergs radiator was installed which has never boiled. The

problem with original radiators is the fins are a push fit over the tubes.

With constant vibration, the fins start to lose contact with the tubes

and the radiator just can't dissipate heat effectively.

The next thing to break was the rear wheel

hub, in December 2015. The reason for this is that a club member who had

worked on my wheels not long after I got my car had filed the spoke ends

so they were no longer a tight fit against the hub. All the forces were

through the bolts and flange, rather than directly against the hub. Luckily

this occurred just as I was turning into my driveway, so no need for a

trailer retrieval. (There is a temporary repair by means of a wheel nut

spanner secured to a spoke which will get the car drivable again).

Upon replacing the hub, I packed it with

shim between the hub and spokes.

Rear hub broken at flange.

A wet drive home, February 2021.