This set has been in my collection for about 18 years, having come from a council clean up campaign, and it's only recently that I decided to have a good look at it. Like all the other GE valve portable sets sold in Australia, it uses Compactron valves.

General Electric portable TV's in

Australia.

General Electric's portable sets are interesting

because they are what brought Compactrons to Australia. The sets themselves

are of U.S. design, which was modified, and then assembled in Australia

by James N Kirby Appliances. Not surprisingly, the sets are series heater

since the U.S. versions do not use a power transformer.

Initially, GE's first portable in Australia

was an 11" set, released in 1964 and designated TF1. This was a U.S. model

SY, which had been adapted for Australian use by supplying an outboard

120V transformer. Additionally, the tuner was a locally manufactured Steane

or MSP type, and of course the video and sound IF were altered for Australian

conditions. Since the 625 line system used in Australia was based on the

U.S. 525 line system used in the U.S., the alterations are simple. Negative

modulation and FM sound is common to both systems. The line frequency is

very close, being 15,750Kc/s for 525 lines and 15,625Kc/s for 625 lines.

Thus, no modification is required for the line deflection circuit. Similarly,

the 60 field frame rate (U.S.) is close enough to the 50 fields used with

the 625 line system that the circuits are the same; the normal frame hold

control having enough adjustment to work on the lower frequency. The main

difference is the 4.5Mc/s sound IF used with 525 lines, whereas it's 5.5Mc/s

with the version of 625 lines used in Australia (system B). Less important

is the different video IF standards.

GE's first portable in Australia was this 11" set using an outboard

240 to 120V transformer. I'm looking to add one to my collection.

It was a popular model, and its release

forced AWA to develop their 11" P1 portable. Externally, the resemblance

was obvious, but internally the AWA set was completely different, using

an entirely local design.

Later, GE released 12", 16" and 19" portable

sets, again based on their U.S. counterparts. By this time, the power transformers

were mounted inside the sets.

Where possible, locally produced components

were used, but otherwise they were imported.

It is interesting to look at the Australian

modifications to these sets. In some cases they are quite crude. The construction

of the sets (and their U.S. counterparts) were clearly made to a price.

Technicians did not like them, since the service access can be very difficult,

and of course, Australian technicians have difficulty with anything but

the usual 6.3V parallel heater valves, which the local industry was based

on. Funnily enough, it's the sets everyone else hates that I like the most!

My first GE Compactron set (16") was bought

for $2 in a second hand shop in 1981. It was inoperative, in that there

was sound but no picture, and back then I really had no idea what its fault

was. I erroneously assumed that since all the valves were lit that it wasn't

a valve fault.

I took it to the local TV repair shop

and the technician didn't want to touch it. He said he'd have to import

any Compactrons from America which would be expensive, etc. I realised

later this was a cop-out because Compactrons were actually standard with

local valve suppliers. Even Tandy had been selling them! Sadly, the set

got pulled apart, and in hindsight, I'm almost 100% sure that the fault

was the damper diode in the 33GY7 was open circuit. On a positive note,

I have since accumulated quite a number of Compactron portables, including

some of the 16" models I had back in 1981. I am looking for one of the

11" GE TF1 models, so if you know of one, please get in touch.

Compactron Valves.

These were designed by GE in the early

1960's as a way of reducing the valve count in a set. Each Compactron contained

two or three valves in the one envelope, and were fitted with a 12 pin

base. Both parallel and series heater versions were produced. In some instances,

the valve sections were based on existing single types. Aside from GE,

National used a compactron (38HE7) in their locally assembled portables

(Japanese models similarly modified for Australian conditions). Otherwise,

Compactrons were ignored by the typically conservative local manufacturers.

They were of course much more popular in the U.S, and several manufacturers

used them. With a printed circuit board, a set using Compactrons could

be made very compact, as the name suggests.

The 15BD11 contains two triodes and one pentode.

The power transformer at the bottom left is a local addition.

Several aspects of the construction stood

out. The first is the MSP (AWA) deflection yoke. The 12" and 16" models

use a narrow neck picture tube, and since no local manufacturers were using

these tubes, locally made yokes for them did not exist, hence they were

imported.

The tuner is a Matsushita (National/Panasonic)

ENR-5759. The ENR-5758 was being used in various Thorn sets produced locally.

There appear to be no obvious differences between the two types. The tuner

bracket has not been altered sufficiently, because with this tuner, the

channel numbers on the knob do not line up perfectly with the indicator.

Since the U.S. version of this set is

120V and live chassis, a power transformer (made by Ferguson), and the

base plate it is mounted on, have been added. It feeds an isolated 120V

into the set. The transformer installation looks quite good in this set.

With the 12" and 16" models, it has been shoe-horned in, and the extra

weight was sometimes too much for the plastic cabinet. This set weighs

about 13kg; no doubt a good deal heavier than its U.S. counterpart with

no transformer.

Like the other models, one can see where

the 120V input socket would be for the original U.S. version.

Of course, the Australian model does not

include a UHF tuner, but it's obvious where it would go, with the front

panel chassis having a cut-out for it. Many of the capacitors are of local

Philips production, and are polyester or polycarbonate. It is fortunate

that GE avoided paper capacitors, and this compensates for the not so good

service access when restoring one of these sets. Resistors are partly IRC,

although there appear to be some U.S. made types, and some others of indeterminate

origin. As such, restoration is mainly resistor replacement, since the

IRC product has not survived well over time.

From the date stamps on various components,

this set was made in 1973. It was of the last generation of locally assembled

valve monochrome set. GE's colour sets which appeared soon after were a

rebadged Hitachi chassis.

Getting it Going.

Not having to replace any paper capacitors

means there's a pretty good chance of something useful happening when one

of these sets is powered up. In this instance, nothing happened. The first

obvious problem was the 38HE7 line output and damper valve was broken.

How this happened is not known. A drop of water down a ventilation slot

onto the hot valve perhaps?

Replacing this restored line deflection,

except this showed up no frame deflection. Again, with the general reliability

of the passive components of these sets I considered the 23Z9 frame oscillator/output

valve might be faulty. Because of the non logical and cramped layout, it's

difficult to trace out the circuit for measurements, so it's easier to

try the valves first. Indeed, another 23Z9 restored frame deflection.

Next, the speaker was completely dead.

The 17BF11 quadrature detector/output valve looked like the getter had

all been used up, so it too was replaced. Now we had some scratching and

faint hum as the volume control was rotated. This left the problem of no

video.

Injecting a signal into the IF at the

output of the tuner didn't show anything, so that at least eliminated the

tuner. Seeing the 9BJ11 video IF amplifier heater looked dull (like it

was almost devoid of vacuum), I replaced it, and we finally had a picture

and sound.

Faulty Compactrons.

In my entire TV servicing career of about 35 years, I have never seen so many faulty valves in the one set. Most sets I have worked on haven't needed any valves replaced, but here were four faulty ones in one go. This is the first time since 1981 that I've encountered a faulty Compactron. The only unusual thing I noted was corrosion on the pins of several of the valves. If this somehow made its way up into the glass envelope, then it would be no surprise for vacuum to be lost. The general appearance of the set when I found it suggested it may have been 'stored' out of doors for a time.

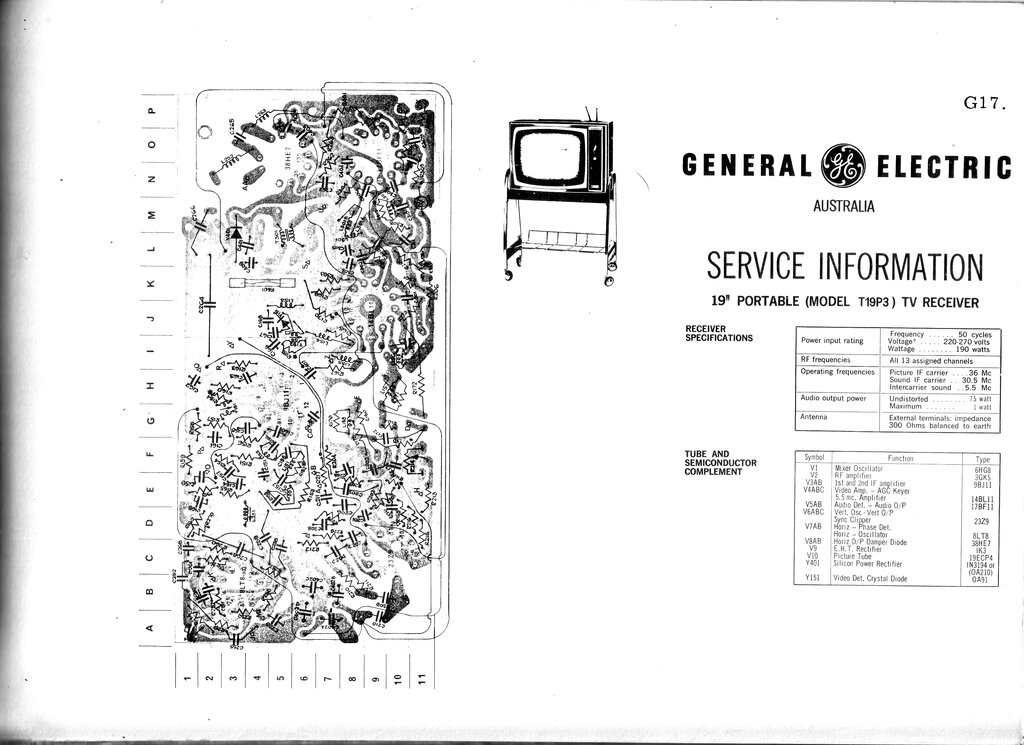

Valve layout diagram. The tuner valve types and heater shunt resistor

are different to what is in this particular set.

With a touch up of the various preset controls, a good picture was obtained.

Cost cutting is evident in that while the picture is sharp, the video bandwidth is perhaps less than it could be. This is not surprising, since with only two stages of video IF amplification, the bandwidth would have to be compromised to obtain sufficient gain. The 9BJ11 does not seem to be of frame grid construction, judging by its characteristics (7500 and 9600 umhos for each section). Nevertheless, the picture is perfectly watchable by the average viewer.

The dark bar is due to the camera shutter.

There was no problem setting the picture

geometry for a round and centered test pattern. The height and linearity

controls, while interactive, are not difficult to adjust. The user adjustable

width control is unusual, and seldom seen. Unlike most 110 degree sets

of local design, the GE does not have a stabilised line output stage, so

it's conceivable the adjustment can be used to compensate for change in

mains voltage.

I discovered that the 1K3 EHT rectifier

had been replaced by a selenium stick rectifier. Whether this had been

done during manufacture or during a later repair is not clear. Seeing as

the modification had been done acceptably, it was left in situ.

Inside the back. Note the power cord entry at the bottom right.

The original 120V input has been blanked off by the locally made decal.

Note the brown rectangular hole towards the bottom right.

Because the Australian set is connected

to the mains with a three core flex, the U.S. method of having a two pin

interlock on the cabinet back can't be used (except for the original 11"

TF1). While the location of the interlock is evident on the chassis, and

the cabinet back, it's blanked off by a locally made aluminium decal. To

get the flex into the set, for this and other models, it looks like a soldering

iron has been applied to the edge of the plastic moulding to melt a suitable

entry slot into it. Needless to say, the cord storage hooks on the cabinet

backs don't accommodate three core flex properly, since they were designed

for twin flex ('zip cord' in the U.S.). This set has no cord hooks, but

it's obvious where they would normally be.

Another peculiarity with this set is the

aerial terminals.

Note the terminals labelled UHF.

They're clearly labelled UHF, even though there's no UHF tuner. There is an indentation in the moulding to the left which could be where the VHF terminals would be in the U.S. version, but since I have not seen one I can't be sure. The 12" and 16" portables are even more crude, using a piece of phenolic fitted with a couple of Fahenstock clips, screwed onto the back over the hole where the terminals normally are. However, in those sets, the reason for so doing is because of the power transformer being in the way.

Back of cabinet. The locally applied decal has not been applied

evenly and is bowed.

Except for the neutralised triode sound IF amplifier, the circuit

is conventional.

Front End.

A conventional VHF turret tuner is used.

Why the aerial isolation components have been included is curious, since

the set has an isolated (and earthed) chassis. Contrary to the circuit

diagram, the tuner installed is a different type, made by Matsushita. It

uses a 4GK5 RF amplifier and 7GS7 converter. These valves are designed

for a 300mA heater string, but since the GE uses a 450mA heater string,

a 75R 7W resistor is shunted across the heater supply of the tuner, to

absorb the extra 150mA.

It's an interesting question as to why

a 3GK5 and 5GS7 were not used, since these have 450mA heaters, removing

the need for the shunt resistor. Presumably the tuners were already supplied

with the 300mA valves, and it would be cheaper to install a shunt resistor,

rather than replace the valves.

The IF from the tuner proceeds to a two

stage amplifier using a 9BJ11 dual pentode. From here, the video is detected

by an 0A91 germanium diode, before proceeding to the pentode of the 14BL11,

which performs as the video amplifier.

Video Amplifier & CRT.

The video stage is entirely conventional,

with the 14BL11 pentode biassed largely by the negative going video signal

from the detector. It's a typical resistance coupled circuit, with a peaking

choke (L157) in the plate circuit, to improve the frequency response. A

high level contrast control is used, this being in the plate circuit. Effectively,

the contrast control is wired as a variable tap-off across the plate load

resistor. Since this type of control is affected by stray capacitance,

compensation is required in order not to lose high frequency response at

certain settings of the control. C170 and C171 perform some of this compensation.

Additionally, it's important to keep the wires to the contrast control

and to the CRT spaced away from the chassis and other wires.

L158 compensates for the cathode capacitance

of the CRT. The CRT is mostly AC coupled, which is typical of American

practice. R177 provides a compromise between full DC coupling, and full

AC coupling. Full DC coupling, while ideal from a theoretical point of

view, can be difficult to implement. It means the picture can be prone

to shifts in brightness, if the black level is not maintained perfectly

at the transmitting end. Also, the AGC circuit must be perfect, since any

change in front end gain will affect the DC level at the video amplifier

plate, and thus the CRT cathode. Additionally, it is usually found that

brightness and contrast controls become interactive, and difficult to adjust

correctly for a non technical viewer.

In short, AC coupling makes for cheaper

set design, and less critical adjustment.

The CRT is a 19" 110 degree 19ECP4. A

series tuned circuit trap for the 5.5Mc/s sound IF (C173 and L159)

is connected right at the CRT cathode on the CRT socket. Brightness control

is by varying the grid voltage relative to the cathode. There is a spot

suppression circuit, to prevent a dot appearing in the centre of the CRT

when the set is switched off. This is a typical circuit whereby the earthy

end of the brightness control is connected via one pole of the power switch.

When the set is switched off, the grid voltage rises towards the B+ before

the filter capacitors discharge. This causes a higher current to be drawn

from the CRT, quickly discharging the remaining EHT voltage.

AGC.

Despite the cost cutting, the set does

have gated (keyed) AGC. This ensures the AGC level is responsive to the

signal only during the sync pulses, and is not affected by the picture

content, unlike the simpler form of AGC (incidentally used in the TF1 model).

This circuit is based around a triode

of the 14B11. This triode functions as a variable rectifier diode, rectifying

pulses from the line output transformer, to create a negative voltage which

controls the gain of the RF and video IF amplifier valves.

It can be seen that since the negative

voltage is generated in synchronism with the line output stage, that the

negative voltage is only produced during the line sync pulses - when no

picture content is present.

As to how much this 'variable rectifier'

should conduct, that's dependent on the triode grid voltage. This comes

from a tapping on the video amplifier plate load, so the grid voltage is

dependent on the strength of the video signal. However, since there is

no plate current in the period between sync pulses, only the grid voltage

during the sync pulses has any affect.

If the sync pulses increase in strength,

the triode conduction increases, creating a stronger negative voltage,

and thus the gain of the front end is reduced, restoring the signal level

to what it should be. A further advantage of gated AGC is that it's amplified,

and a larger control voltage is available, than if the video detector voltage

is used directly. This is important in areas with high signal strength

where simple ACG might be overloaded. Finally, because the AGC circuit

is dependent on line sync pulses only, the time constant can be made short,

which allows the set to respond quickly to rapidly fading signals.

Sync Separator.

Based around a triode of the 23Z9, this

clips the video signal so that only the sync pulses are present. It operates

under typical conditions with no initial bias and a low value of plate

load resistor. In other words, it's deliberately designed to distort the

signal so that only the peaks appear at the plate. A simple filter

circuit separates the line and frame pulses from the output. R202, R203,

and C202 and C203, form a low pass filter which allows the 50c/s frame

pulses through, but shunt the higher frequency line pulses to earth.

Conversely, the line pulses pass through

C251 relatively unimpeded. Its reactance is low enough to pass the 15,625Kc/s

line frequency, but high enough to ignore the frame frequency.

Vertical Oscillator & Output.

This uses the remaining triode and pentode

of the 23Z9 in a conventional multivibrator circuit. The triode generates

a 50c/s sawtooth which feeds the output pentode. A complex feedback circuit

compensates for the high plate resistance of the pentode, so that good

linearity can be obtained. The oscillator triode plate voltage comes from

the 400V boost supply. This is conventional and is done because it provides

a more constant current through the plate load (R208), than if the ordinary

B+ was used. This in turn provides a better shaped waveform.

The output pentode operates with the cathode

earthed, and as such, its bias is obtained by grid rectification of the

incoming sawtooth waveform. A thermistor (R269) compensates for changes

in deflection coil resistance as the set warms up. The height and linearity

controls are very interdependent, and in fact the labels are sometimes

reversed with other sets.

Positive feedback from the pentode, to

cause oscillation, comes via C209, R210, and C204 into the grid of the

triode. Negative feedback for linearity correction comes via C209, R211,

R212, and into the triode plate (and thus the pentode grid) via C208 and

R209.

Line Oscillator & Output.

The line oscillator is a Colpitts type,

based around the pentode of an 8LT8. This valve has a normal 9 pin base.

No doubt to ensure a strong drive to the line output stage, the plate voltage

comes from the 400V boost supply. As is typical with sets used with negative

modulation systems, there is an AFC circuit for the line oscillator. This

uses the two diodes of the 8LT8, and compares the line oscillator frequency

with that of the sync pulses. The output of this circuit is a DC voltage

that varies depending on how far apart the two are. It acts as a correction

voltage, so that if the line oscillator is off frequency, the voltage generated

pulls the oscillator back to the correct frequency. The reason for using

this method of control is to prevent noise pulses triggering the line oscillator

directly. With the negative modulation system, noise pulses are the same

polarity as the sync pulses. Having DC control of the line oscillator means

a time constant can be incorporated, which filters out the noise.

The line output is the pentode section

of a 38HE7. This is a higher power version of the 33GY7 which was used

in the smaller portables. The damper diode is also incorporated in the

38HE7.

EHT rectification is shown as being done

by a 1K3, which is an octal valve. In my particular set, a selenium rectifier

has been fitted instead.

Sound IF, Detector & Output.

The 5.5Mc/s sound IF is taken from the

plate circuit of the video amplifier. This allows the video amplifier to

contribute useful gain for the IF signal. The sound IF amplifier itself

uses a triode of the 14BL11. Using a triode here requires the stage to

be neutralised. This is done by C304, which feeds an out of phase voltage

into the grid. It's an unconventional circuit, but it does work. Presumably

the gain is not quite as high as if a pentode had been used. Another interesting

aspect of design here is that the sound IF transformer is shunt fed from

the triode, which has a plate load of 47k (R305). Normally, the transformer

primary would be carrying the plate current on its own.

The FM signal is detected using one section

of the 17BF11. It is a quadrature detector circuit, and this valve is specifically

designed for this use. In very simple terms, a coil in the suppressor grid

circuit (L302) oscillates at 5.5Mc/s. The incoming FM signal applied to

the control grid is compared to this fixed 5.5Mc/s, and as the frequency

varies, so does the electron stream, and thus the plate current.

The detected output is of sufficient amplitude

to drive the audio output valve directly. Again, feeding the plate resistor

from the 400V boost supply increases the audio level. The output stage

is the power pentode section of the 17BF11. It is interesting that the

bias for this valve relies partly on a bleed resistor from the B+ (R310),

so that the cathode resistor (R309) can be of lower than normal value.

Presumably this was done to avoid using a cathode bypass capacitor, since

the higher the value of an unbypassed cathode resistor, the more negative

feedback there is, and more loss of gain.

Power Supply.

In the U.S. version of this set, the incoming

120V mains is half wave rectified, producing a B+ of 148V. Pi filtering

is used, comprising of L401 and R401, along with three electrolytic capacitors

in the can of C402.

The valve heaters are connected in series

across the 120V supply. No dropper resistor is required, since the valves

have been designed so that their heater voltages add up to 120V.

The Australian version of the set has

a 240V to 120V power transformer added, since 1), Australian technicians

don't like live chassis sets, and 2), a heater dropper resistor would be

required, which would give off excess heat for the heater voltage and current

required. Sets for 200-250V mains with series heaters use 300mA heater

valves, which eases the situation considerably. Unfortunately, adding the

transformer adds noticeably to the overall weight of the set. Even with

my good degree of fitness, I find it difficult to carry.

It is interesting to speculate that if

GE in Australia had modified the rectifier to be full wave, perhaps a smaller

transformer could have been used, since there would not be any DC flowing

through the transformer, as is caused by half wave rectification. DC flowing

through a transformer causes losses from core saturation, and the core

has to be larger (heavier) than if no DC is present.

The T19P3 and T19P4 use the same chassis.