The Model T Ford Battery

and Charging System.

Part 1 - Know Your

Battery.

The first thing the Model T owner wants

to know when presented with a flat battery is whether it is the battery

or the charging system at fault.

In order to narrow down the cause of the

problem, it helps to first have an understanding of the battery and what

to expect from it.

The lead acid battery.

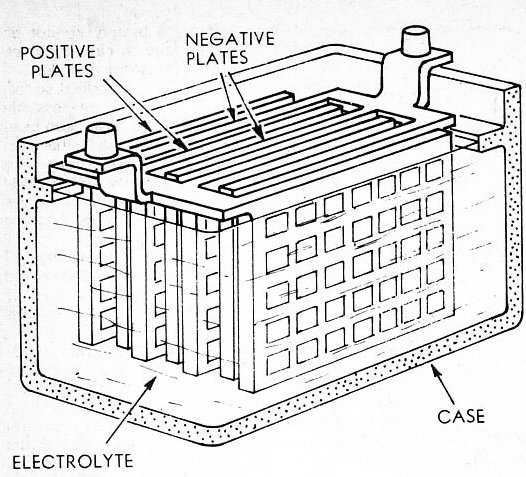

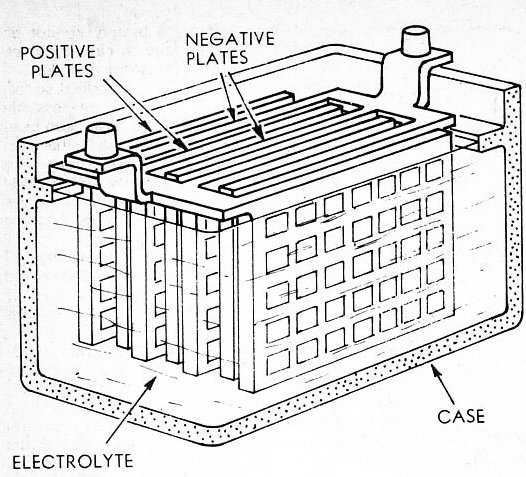

To use the correct terminology, a “battery”

is formed by more than one “cell” being connected together. A lead

acid cell produces 2 volts, regardless of the number, or size, of plates

it has. Thus, to obtain 6 volts, three cells are required, or six for a

12V battery.

In each cell, two sets of lead plates

are immersed in a mixture of sulphuric acid and water, otherwise known

as “electrolyte”. To charge the cell, external current is connected to

the plates.

Without going into detail of the chemical

reaction that occurs, it is sufficient to say that when the battery is

charged, the acid is stronger than when the battery is discharged.

As the battery is discharged, the plates

become coated with sulphate which comes from the acid. This reduces back

to lead when the battery is charged again.

Internal parts of a typical 2 volt lead acid cell.

Because the acid strength is dependent

on the chemical condition of the plates, this can be used to determine

the level of charge. Typically, the specific gravity of the acid is about

1.25 when charged, and 1.11 when discharged. This means the acid has 1.25

and 1.11 times the density of water respectively.

To measure this, a hydrometer is used;

the level at which the internal float sits provides the specific gravity

reading. Hydrometers are becoming obsolete, so far as the average motorist

is concerned, partly because they are messy to use, and partly because

of the increase in “maintenance free” or otherwise, sealed batteries. With

the high accuracy of low cost volt meters now available, it is more convenient

to measure the battery voltage to ascertain charge level.

The voltage of a lead acid cell is 2.2

-2.3V upon completion of charge. This rapidly falls to around 2.1V and

remains there until the cell has current drawn from it. At 1.8V, the cell

is at a very low charge. These figures are multiplied by three or six,

for 6V and 12V batteries respectively.

The Hydrometer is an inexpensive

instrument for testing charge level.

Battery capacity.

Every battery has an amp hour capacity,

which is often specified at a 20 hour rate. A typical Model T size 6 volt

battery has about 80 amp hours.

This means that one could draw 4 Amps

for 20 hours before the battery is discharged. The capacity increases for

a lesser current drain, and decreases for greater. This is why it is not

possible to run the starter motor for more than a few minutes, even though

the calculation would suggest 40 minutes cranking time with 150A starter

current. Knowing the battery capacity is useful to determine how long it

can be used for, before being discharged. Pertinent to this are the Model

T’s which have electric lights, or ignition, run from a battery, but no

generator. A common question is, “how long can the lights be used for,

before the battery goes flat”? First thing is to know the current draw

with lights and ignition on. Assuming this is found to be 10A, and the

car has a 100Ah battery, then 10 hours would be the theoretical maximum.

Because of the 20 hour rate, the time will actually be less, and if the

battery is old or in poor condition it will be less again. Nevertheless,

it gives a rough idea of what to expect. Typical experience suggests about

half the running time to that calculated.

What about “Cold Cranking Amps”? This

is an indication of the ability to maintain voltage under the high load

of a starter motor. It is expressed in hundreds of amps, and is how much

current the battery can actually provide instantaneously, rather than how

much it can store.

Types of battery.

Lead acid batteries also come in forms

other than the familiar type with removable filler caps, which has been

around for over a century.

So called “Maintenance Free” batteries

became popular in the early 1980's. These are really just ordinary wet

cell batteries without filler caps. More than the normal amount of electrolyte

is added to the cells, hoping that by the time it has evaporated, the owner

thinks an adequate life has been had from it. Some enterprising motorists

did in fact discover filler caps underneath the moulding in the battery

top with some types, or simply made holes in the tops of others, to inject

water.

In recent years, the Sealed Lead Acid

type has become popular. These go under such brand names as “Optima” or

“Orbital”. The generic name of “Gel Cell” is often used for the smaller

non automotive types. The operating principles are the same as the wet

cells, but the electrolyte is in paste form. This means the battery can

be used in any position without spillage. Small SLA batteries are popular

with owners of non electric T’s for ignition coils and low powered lighting,

because they can be stored unobtrusively under the seat without acid fumes

and spills.

However, the cells are not intentionally

vented to the atmosphere. This means hydrogen production must be kept at

a minimum. Because of this, charging requirements are far more stringent,

and normal car battery chargers are not suitable for the smaller batteries

due to the likely risk of overcharge.

For the Model T owner, the "Red Top" Optima

is highly recommended. It uses a spiral wound plate assembly. While it

is much more expensive than a conventional wet lead acid battery, the lack

of acid migration over the battery terminals and surrounding metal work

is welcome, as is never having to maintain it. Importantly, life is longer

than a conventional battery, but also the internal resistance is lower

which provides for better starting. It should however be used with a voltage

regulator, and these are discussed further on.

Optima sealed lead acid battery.

Discharging.

Allowing a lead acid battery to get below

about 1.8V per cell will cause irreparable damage. When this happens, excess

sulphate builds up on the lead plates, insulating them from the electrolyte.

A classic scenario is the flat battery because the lights were left on

all day. Just one bout of this causes irreversible plate sulphation. Even

though a charge the next day may make it appear that all is well again,

the capacity is likely to be reduced. The battery will now no longer have

its full life expectancy and soon the owner may find the need to occasionally

use a mains powered battery charger, when previously the car’s own charging

system was sufficient.

Self discharge causes just as much damage.

All batteries discharge by themselves, even if not connected to anything.

Many a Model T has suffered the death of a battery from self discharge

through lack of use. Unfortunately, merely charging the battery the night

before a drive, after the car has sat for a few months, will not reverse

the deterioration. Fortunately, it is possible to keep the battery fully

charged at all times, and this will be explained further on.

Note also, there are instances of a faulty

electrical system being responsible for a high rate of discharge, leading

one to think the battery is faulty. Particularly prone to this are cars

with modified charging systems, which with incorrect wiring may well charge

the battery, but still draw current when everything is turned off. A very

simple test for the possibility of this fault is to connect an automotive

test lamp between one of the battery terminals and associated battery post.

With everything switched off, any leakage will be indicated by the test

lamp. Those proficient with multimeters can do the test with more accuracy,

but starting on the 10 amp DC range and reducing the range as necessary.

Unfortunately, the Model T dashboard ammeter

is not sensitive enough to show low levels of leakage.

Part 2 - Battery Charging

and Maintenance.

Correct charging.

It may be a surprise to know that a good

quality lead acid battery can last 10 or more years if it has always been

correctly charged and maintained from new, and never allowed to discharge.

Lead acid batteries are the simplest of

all types to charge.

The ideal method is to apply current to

the battery until each cell has come up to 2.4V (i.e. 7.2V for a 6V battery),

or the specific gravity is 1.25. Then the voltage is dropped to maintain

the charge at 2.3V per cell. Failing to stop charging at the higher voltage

will cause excess gassing and loss of electrolyte. This is most important

to avoid for sealed batteries. Unfortunately, the standard Model T charging

system is very much of a compromise, and does not terminate charging at

all. This will be examined later to see how the undesirable effects can

be minimised.

Note that the specific charge voltages

can differ slightly for different batteries, but this is usually available

from the manufacturer's specifications.

In practice, conventional wet lead acid

batteries are forgiving enough to tolerate some overcharge, which invariably

occurs with simple charging systems.

Charge Current.

What current is the best to charge at?

Over the last century of battery technology, it has been found that a good

rule of thumb is about a tenth of the battery capacity. So, it’s no coincidence

that the typical low cost car battery charger is rated at 4-6A, for the

common 50Ah 12V type of battery. Those with 6V batteries can usually charge

at around 8-10A. If you’ve followed everything so far, you can probably

guess that the time taken to charge a totally flat battery at this rate

will be 10 hours. In practice, because the battery is not 100% efficient,

up to14 hours are recommended.

A battery can be charged much more rapidly

with higher current, but this should only be done in an emergency, as the

high current can buckle the plates, overheat the electrolyte, and cause

excess gassing. The charging must be terminated immediately the charge

is sufficient. Even so, this kind of treatment is detrimental to its life.

Of course, a battery can be charged at

a lower rate, but will simply take longer.

It is important to note that the gas vented

from a charging battery is hydrogen, and that explosions have occurred.

Usually, this is when battery chargers or other items are connected or

disconnected from a furiously bubbling battery. The spark produced ignites

the hydrogen surrounding the battery. This is why the instructions for

jumper leads often state to make the negative connection to somewhere on

the chassis away from the battery. Chargers should be turned off at the

mains before connecting or disconnecting from the battery.

Types of Chargers.

In practice what does all this mean for

the Model T owner who needs to charge the battery from the mains? The basic

low cost battery charger works well enough here. This is the kind of charger

that puts out about 4A and includes a simple ammeter. The circuitry of

such a charger is essentially just a transformer and rectifier. It does

not contain any voltage regulation. With it one also needs a hydrometer

and/or digital volt meter to check the charge – this can be done every

few hours or so. The key point is to not leave the charger on for more

than necessary. A time switch is a good idea if the charger has to be left

unattended.

In the modern day, so called "Intelligent"

chargers have become available, which can be connected indefinitely. These

provide the ideal charging conditions, in that the battery voltage is taken

up to 2.4V per cell, and then dropped to 2.3V, at which the battery is

maintained but not overcharged.

Some simple chargers have a LED bar graph

voltmeter to show the charge level. Beware that these types do not shut

off when full charge is shown, unless the specifications say otherwise.

While the “Optima” kind of sealed car

battery is rugged enough to be charged with conventional chargers (although

not recommended for long term use), the smaller “Gel Cell” types are not.

The high current will damage the internals and the electrolyte will dry

out. Special chargers are available which should be used.

Battery Maintainers.

Becoming popular among vintage car owners,

these solve the problem of battery self discharge, when the car is not

used for long periods. The maintainer is connected to the battery whenever

the car is garaged, and keeps it at 6.9 or 13.8V. Thus, the battery does

not discharge, and because the voltage is fixed, it cannot overcharge.

The ideal state of equilibrium is reached, eliminating the need to constantly

check water level or charge state. The battery is always ready for use

at full charge. Unlike chargers, maintainers are a precision unit, and

provide only enough current to offset self discharge. To charge a flat

battery from one would take several days, if not longer. The Model T owner

should therefore keep a conventional charger, as well as a maintainer.

As previously described, many "Intelligent" chargers do combine charging

and maintaining, and are a more convenient option.

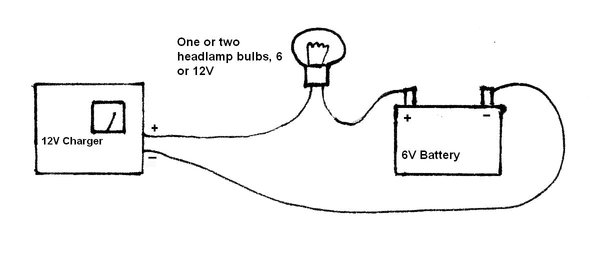

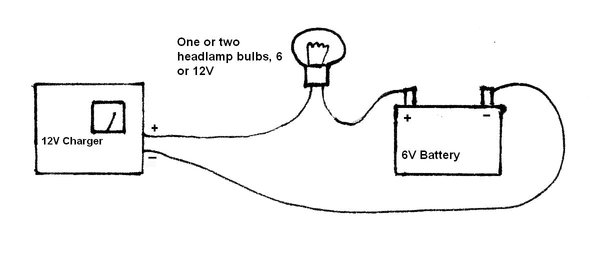

Charging a 6V battery from a 12V

charger.

While 6V battery chargers are available,

it is possible to charge a 6V battery from a 12V charger. All that is required

is one or two headlamp bulbs. These serve to limit the charge current,

and absorb the extra 6V. Start by connecting the 12V battery charger to

the 6V battery with one bulb in series with one of the connections. The

bulb will light to show charging is taking place. If more charging current

is required, connect an extra bulb across the first. It does not matter

if a 6 or 12V bulb is used because the difference in voltage between the

charger and battery will be around 6V.

It is quite practical

to use a 12V charger with a 6V battery as shown above.

The basic kind of charger is necessary

here, as types that monitor the voltage will be confused. It is not possible

to use a 12V maintainer or intelligent charger with a 6V battery this way.

Pills and Potions.

Since cars were first fitted with lead

acid batteries, all sorts of additives have been made available to the

gullible motorist, in order to rescue an unusable battery. Generally, these

are intended to break down the excess sulphate. In recent years electronic

devices have become available which pulse a high voltage through the battery

to do the same thing. Results appear to be quite variable, and it can take

quite some time to achieve the desired effect. Whether or not these methods

are successful, it is highly doubtful that full performance can ever be

restored.

Testing a battery.

Usually, a battery only gets tested when

something is amiss – the battery has been charged but the lights are still

dim, etc. The first thing to do is check the electrolyte. At least 50%

of problems are because of electrolyte being below the tops of the plates.

Distilled water should be used to top up.

The next thing to do with an apparently

faulty battery is charge it off a mains powered charger, so as to eliminate

the possibility of a faulty electrical system in the car. If the ammeter

on the charger is showing very low current, this is indicative of one or

more faulty cells. One can wait a few hours to see if charge current increases,

but it is likely the battery is ruined. Sometimes, it is noticed that by

touching the side of the battery, that one cell is warmer than the others

– this is also a sign of failure.

At the end of the charge period, each

cell should be checked with the hydrometer. A cell with low specific gravity

while all the others are high also indicates problems.

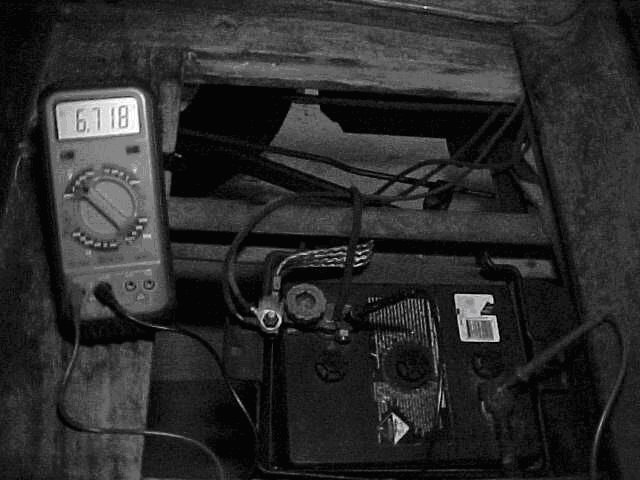

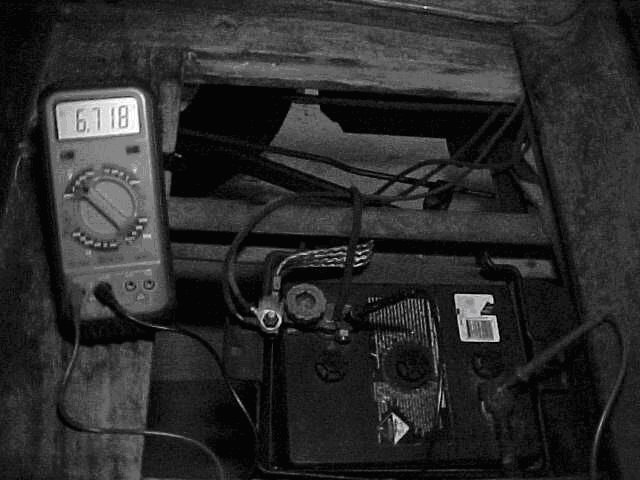

The simplest test is then to run the battery

into a load after a full charge. For this, the car’s headlights are ideal.

Measure the voltage at the actual battery posts, with the lights on. Do

not measure the voltage anywhere else, as wiring resistance will give a

false reading. If it drops below 6 or 12V the battery is faulty.

Taken off the maintainer before this reading was taken, 6.7V shows

the battery to be in good condition.

With a faulty battery, the voltage often

drops in multiples of two; each loss of two volts indicating a defective

cell.

Part 3 – The Ford Generator.

With commercial pressure forcing Ford to

eventually adopt the electric starter, a lead acid battery had to be included,

as the current drawn by a starter motor is too high for any kind of dry

battery.

A means of recharging the battery was required, so a generator driven by

the car engine was the obvious solution.

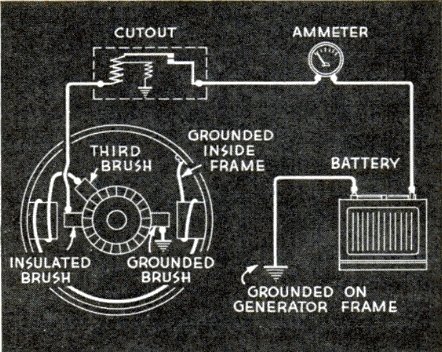

Generator Principles.

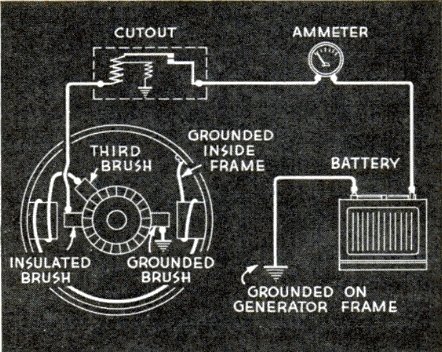

.

.

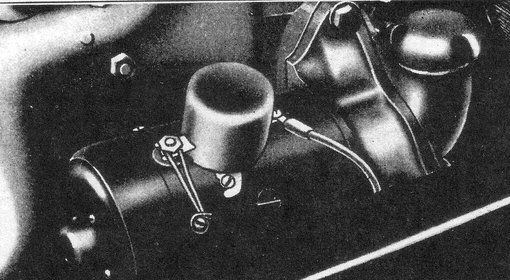

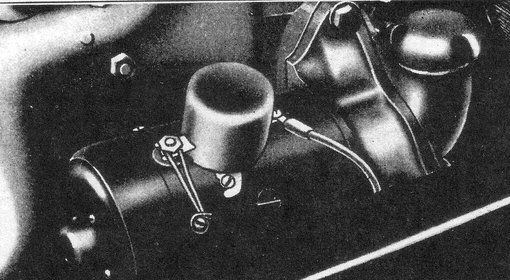

Essential parts of a charging

system using a 3rd brush generator.

As is well known, a generator works on

the principle of an electrical conductor (the armature windings) rotating

in a magnetic field (developed by the field coils fixed to the generator

body). The strength of this magnetic field, in turn, controls the generator

output current. Thus, by controlling the current through the field coils,

the charge rate can be set to a particular current.

This is the purpose of the third brush.

Without going into the complexities of what really happens, it is sufficient

to know that by sliding the 3rd brush towards the insulated brush, field

coil current increases, and therefore the battery charge rate. A simple

way of explaining this is to think of the voltage gradient across the armature,

starting at the grounded brush (0 volts), and going towards the insulated

brush (6 volts). By connecting to the armature at an intermediate point

via the 3rd brush, it can be seen how the current fed into the field coil

can be varied.

No Voltage Regulation.

The generator fitted to Fords between

1919 and 1938 is of the 3rd brush type.

This kind was chosen because it fits in

with the “simple but practical” theme. It does not require an external

current regulator, as do two-brush type generators. Over a wide range of

driving speed, the charge remains reasonably constant. However, there is

no voltage regulation. What this means is that once the battery has reached

full charge, (about 7 volts), it continues to be charged at the full rate,

which shortens battery life.

The concept of voltage regulation was

well known at the time, and in fact many other cars of the T era did use

it. A voltage regulator works by reducing field coil current when the battery

reaches full charge. However, Ford, and others more interested in economy,

decided they could ignore it.

The idea was simply to set the charge

current to the lowest point before a flat battery is likely. The problem

now is that when high currents are drawn (e.g. headlights), the battery

won’t fully recharge. Alternatively, if the charge current is set high

enough to allow the headlights to be used, without discharging the battery,

the battery will be overcharged when the headlights are not used.

A compromise has to be reached in this

situation, but the 10 to 12 amps as recommend in the Ford Service Manual,

is too high for driving conditions in the modern day.

Charge Current.

What should one set the charge current

to? Firstly, the generator maximum power is 100 watts. This translates

to 16A for 6V, or 8A for 12V, before excessive wear or burn out results.

Ford’s idea of setting charge current

is based on being able to run the headlights continuously without having

a flat battery. However, it is enough to damage a fully charged battery

on a long drive when the headlights are not used – which is typical of

Model T driving today. As the standard electrical system draws little current,

the charge rate does not need to be very high at all. What of the huge

current drawn by the electric starter? While it may be around 150 amps,

remember it is for a very short period. To explain this, consider one minute

of electric cranking. Drawing 150A for one minute is the same as drawing

2.5A (equivalent to one brake lamp) for one hour. Put in perspective like

this, it is clear the overall energy consumption is actually very low.

It is for this reason one hears of non

generator cars being able to tour for a week on one battery charge.

Over a long period of time, I have found

5A to be the ideal charge current for a 6 volt system. This accommodates

occasional use of the headlights and starter, as well as the ignition coils

full time. 5A is not so high as to cause excess electrolyte loss. Typically,

the battery might need topping up once or twice a year. My first Model

T battery provided ten years of service, and never went flat.

For those with 12V systems, the charge

rate should be roughly halved; about 3A.

Running on no load.

As the armature spins and produces current,

the field coils become more energised, causing the armature to output more

current, which energises the field coils even more. It’s obvious that a

runaway condition exists, and the generator will soon burn out, unless

the output voltage is limited. As there is no voltage regulator, the only

thing to do this is the loading by the battery. If for any reason, the

battery becomes disconnected whilst the engine is running at speed, there

is a real risk of a burnt out generator. This is especially so where the

generator has been set to a high charge current. Setting it to a low current

like 5A will provide some protection if this situation occurs.

Not only that, any accessories in use

will be damaged from excessive voltage. Such a scenario does happen, and

is often the result of a faulty cut-out, battery isolation switch, loose

terminals, or even a faulty battery. This is the likely fault if light

bulbs start mysteriously burning out at a rapid rate.

There is also the situation where some

T owners wish to run an unconnected generator, because there is no battery

or charging system in the car.

The generator terminal must be earthed when running into no load.

The cut out need not be present.

This can be done quite safely simply by

earthing the generator terminal. Some may wonder, “Won’t shorting out the

generator overload it?” The answer is no, because the armature is prevented

from creating any voltage, which then prevents the field coils producing

a magnetic field.

Typical Generator Faults.

Apart from the usual faults that occur

with any brush type motor or generator, such as worn bearings, worn brushes

or scored commutators, there are some common faults pertinent to the Model

T generator:

• Unless the generator has been reconditioned

with a new brush plate installed, any attempt to adjust the 3rd brush is

likely to destroy an original brush plate. The original material used for

this tends to crumble where the brush is tightened. The result is a short

circuit to ground, and is one of the most common causes of no generator

output. There is an excellent fibreglass reproduction which overcomes this

problem.

• Despite years of being soaked in oil,

the windings appear to be quite reliable, except where charge current has

been excessive. Crumbling insulation and charred windings means a trip

to a rewinder, and if one has ideas of using 12V, the generator should

be rewound to suit.

• When removing the back of the generator,

note exactly where the field coil wires connect to the brush plate, before

any further disassembly. Note the crossover of wires. If these should be

connected in reverse, the generator can be set up in the normal way, but

causes a rather high discharge current when an attempt is made to set the

third brush in the car with the engine running. The reason is that this

reverses the direction of rotation.

Flashing the Generator.

If a generator is in good condition but

fails to produce an output, it may need to be “flashed”. Going back to

the principles of operation, it may be wondered, how can the armature produce

output to energise the field coils which are needed to make the armature

produce output in the first place?

The answer is that there is a small amount

of residual magnetism, in the iron core of the field winding. It is not

much, but enough to start the process.

Where does this residual magnetism come

from? When the generator is manufactured, it is “flashed”.

If a generator has lost its residual magnetism, flashing will restore

it.

For the Model T, the simplest way to do

this is simply bridge the cut out terminals for a second or two. This feeds

battery current into the generator windings and remagnetises the core.

Flashing is also required if a generator from a positive earth system is

to be changed to negative earth.

The residual magnetism may be lost if

the generator has not been used for many years. If flashing is regularly

required, it would indicate commutator or winding problems – the losses

being too high to allow the residual magnetism to start the process.

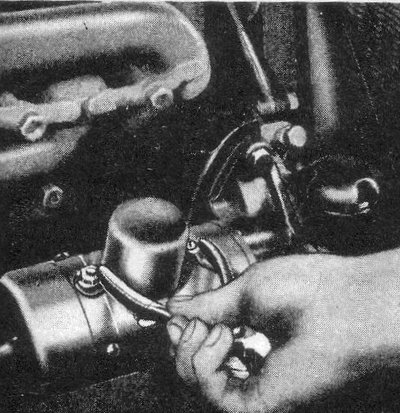

Setting up the Generator.

After all the details given so far, actual

setting of the generator is very easy.

If the generator has been dismantled or

worked on, it is necessary to first set the brush plate. First the generator

is removed from the car. The third brush is then lifted from its holder

so as not to make contact. Then, the four brush plate screws are loosened

just enough so the brush plate can be rotated. Now, with a set of jumper

leads, connect a 6 or 12V battery. The generator will now run as a motor

(incidentally, a quick go/no go test). Move the brush plate in one direction,

then the other. At a certain point, the motoring stops and then reverses

direction. It’s at this point where it doesn’t move, that the brush plate

needs to be tightened. Now return the 3rd brush to its original position,

and again the generator will run as a motor.

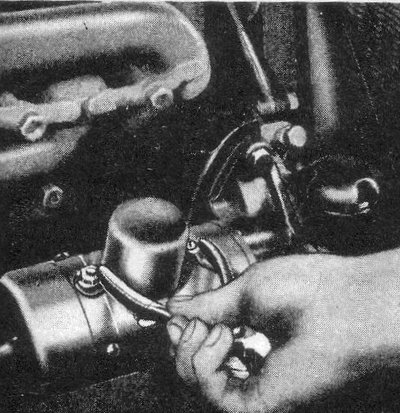

Reinstall in the car, start the engine,

and run at a fast idle. The third brush can now be adjusted by loosening

it and sliding it across the brush plate until the desired current is obtained.

Retighten without crushing the brush plate, and adjustment is done. No

further adjustment of the brush plate is required, even if the current

is readjusted, unless internal work is done to the generator.

Part 4 – The Model

T Cut-Out

Often a source of confusion, cut outs and

regulators are two different things. As described previously, the standard

Model T incorporates a cut-out only.

What is its purpose, and why is it necessary?

The Cut-Out Function.

If the generator were to be connected

directly to the battery, it would certainly provide a charge in the normal

way, so long as the engine was rotating, at or above a fast idle. However,

when the engine slows down or stops, the battery current would now flow

back into the generator, and try to run it as a motor. This is obviously

undesirable, because not only will the battery discharge, but the generator

will sit in a stalled condition, and its windings will soon overheat.

The immediate solution to this is to have

a switch to connect the generator to the battery when it runs above a certain

speed, and disconnects it when it slows down. A simple switch operated

by the driver, could indeed perform this function. However, the possibility

of not remembering to use the switch at the right time makes this idea

impractical. The switch needs to be automatic.

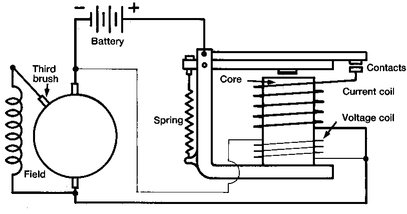

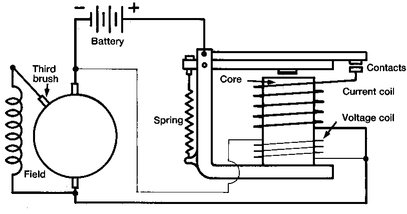

How it works.

The cut-out is rather similar to a horn

relay in internal appearance and operation. One difference is that there

are two windings on the core instead of one. When current is passed through

windings around the core, a magnetic field is developed which attracts

the contacts together, completing the battery to generator circuit.

Expanding on this, we will just examine

the voltage coil first. Note that it connects directly across the generator

output. Now imagine what happens as the generator is brought up to speed.

The magnetic field starts to build up in the core, and when strong enough,

the contacts close.

At this point it can be seen that current

can now flow to the battery, via the contacts and the current coil.

The current coil is only a few turns of

heavy gauge wire, so it has no effect on the charge current. It does, however,

develop a magnetic field of its own. This adds to that already developed

by the voltage coil, and the contacts remain closed. The battery thus starts

charging.

So far, we have accomplished the task

of automatically “turning the switch on”.

Operation becomes slightly more complicated

when the generator slows down and we want the battery to disconnect again.

What happens now?

Keep in mind that the contacts are still

closed, meaning the battery is connected to the generator. But this also

means the battery is connected to the voltage coil, which will keep the

contacts closed, and now the battery will discharge through the generator

and voltage coil.

Indeed it would, except this is where

the current coil comes into play. Consider that when the generator stops,

the current now flows from the battery into the generator. The current

has reversed direction, therefore reversing the magnetic field around the

core. Being in the opposite direction, it cancels out the voltage coil

field, and now the contacts open. The battery is now isolated from the

generator and cannot discharge.

Cut-Out Adjustment.

The only adjustment is the voltage at

which the contacts close. If it is too low, the battery will discharge

through the generator when its output is too low to provide a charge.

If it is too high, the battery will not

start charging except when engine speed is higher than normal.

The cut out is thus set to close when

the generator voltage has reached the level just above that of a fully

charged battery; i.e. about 7.5V.

The adjustment is most easily done using

a variable power supply connected across the voltage coil, and setting

the contact tension so the contacts close just as the supply reaches 7.5V.

Failing the availability of a variable power supply, the generator itself

can be used. An analogue voltmeter connected across the generator

output can be used to measure closing voltage.

Cut -Out Faults.

The construction methods used for the

original cut-out means that those using them really need to do a rebuild.

Remember, a cut-out that does not close can result in a burnt out generator.

The problem is the internal electrical

connections rely on rivets, which loosen over time. Additionally, the insulating

material used crumbles away, making a short circuit possible.

A piece of blank fibreglass printed circuit

board is ideal for replacing the insulators, but any similar high temperature

insulating material can be used.

All riveted connections need to have short

lengths of wire soldered across them.

Inside a reproduction Ford cut out. Failure of any of the internal

parts, or connections thereto, can result in a damaged generator.

Sticking contacts are likely to show signs

of pitting, so by means of a file these can be repaired. Sticking points

will show up as a discharge reading on the ammeter with everything in the

car switched off.

Diode Cut-Out.

In view of potential problems with mechanical

cut-outs, some owners replace the internals with a diode. A diode will

easily fit in space formerly occupied by the relay, but it will need proper

cooling. With a charge current of 5A, heat dissipation will be around 5

watts with a silicon diode, so some kind of heatsink is required. A Schottky

diode has a lower voltage drop and will thus dissipate less heat.

The type of diode is not critical, except

it should have a high current rating. For reliability, something in the

region of 25A or more should be used. Diodes extracted from modern car

alternators are a popular and effective substitution, although Schottky

diodes will run cooler, and not need as much heatsinking. A disadvantage

of solid state diodes is that if they fail, they usually do so in the form

of a short circuit. If this happens, the symptoms are the same as stuck

points with a mechanical cut-out.

Ground Switch.

An idea made popular by an old “Tinkering

Tips” article, was to install a switch to earth the generator terminal,

when charging wasn’t required. A supposed beneficial side effect was that,

with the generator not providing any power, a certain amount of horsepower

would be saved. However, we must realise that with many such articles,

“tinkering” was an apt description, and were without any scientific or

methodical basis. At a speed of 60km/h and a charge current of 6A, the

power consumed by the generator is only 0.18hp. To put things in perspective,

one horsepower is 746W, which equates to over 100A charge current! For

those that still want to try the idea, note that it must only be used with

diode type cut-outs. This is because when in operation, a mechanical cut

out provides a direct connection to the battery. Grounding the generator

when the cut-out contacts are closed will result in a destructively high

current flow before they open. If one could be absolutely certain the grounding

position was only selected with the engine at idle speed, or switched off,

one could get away with the scheme with mechanical cut-outs. But, human

nature being what it is, would eventually mean the switch was operated

at the wrong time.

Voltage Regulators.

As explained previously, the cut out has

no regulation feature. That is, it does not terminate the charging when

the battery is full. While the technology to deal with this was available

at the time, Ford chose not to use it until the late 1930’s. Some T owners

therefore, have adapted regulators from other cars to use with the Model

T generator. This is quite in order, but it does require that the field

winding be brought out to a separate terminal on the generator. However,

given the appearance of Model T specific regulators in recent years, such

a modification is scarcely worthwhile.

Fun Projects Voltage Regulator.

This modern accessory is recommended for

those who wish to overcome the limitations of the stock charging system.

It means one can charge at 10A (at 6V) without overcharging the battery.

Essentially, it contains a diode cut-out, and also an electronic grounding

switch, which cuts off the generator output when the battery is charged.

Generator wear is less, because it’s operating only for a short period,

rather than continuously. It eliminates problems with mechanical cut-outs,

and most importantly, eliminates battery overcharge. In effect, a modern

charging system is gained with no modifications to appearance or wiring.

The unit is simply a drop in replacement for the original cut out.

However, Fun Projects has ceased to exist,

and the regulator is no longer manufactured. The whole story of the Fun

Projects regulator is explained here https://www.cool386.com/regulator/regulator.html

A New Voltage Regulator.

In view of the advantages of voltage regulation,

and that there was a constant demand for regulators, I was involved in

the design of a replacement, which is now being manufactured by another

MTFCA member. This is described here https://www.cool386.com/ford_regulator/ford_regulator.html

Home

.

.